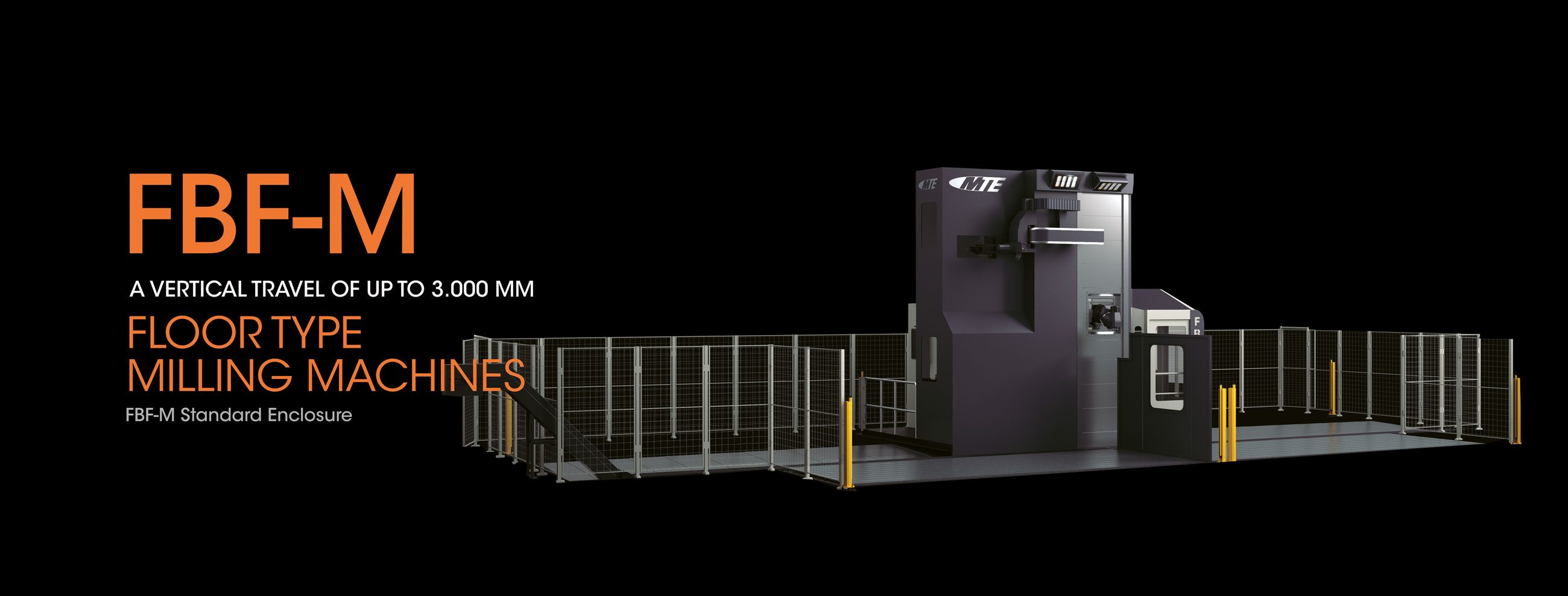

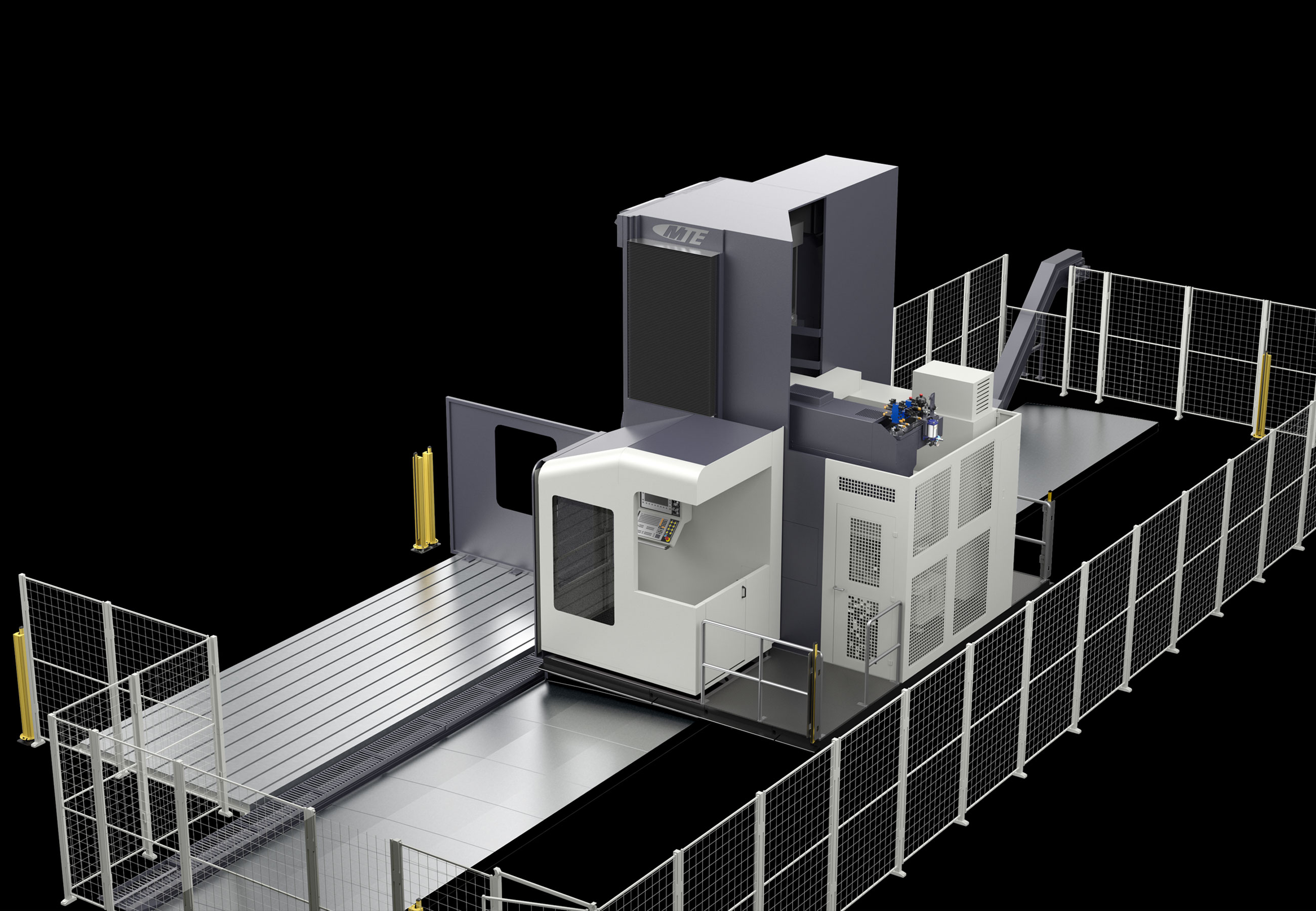

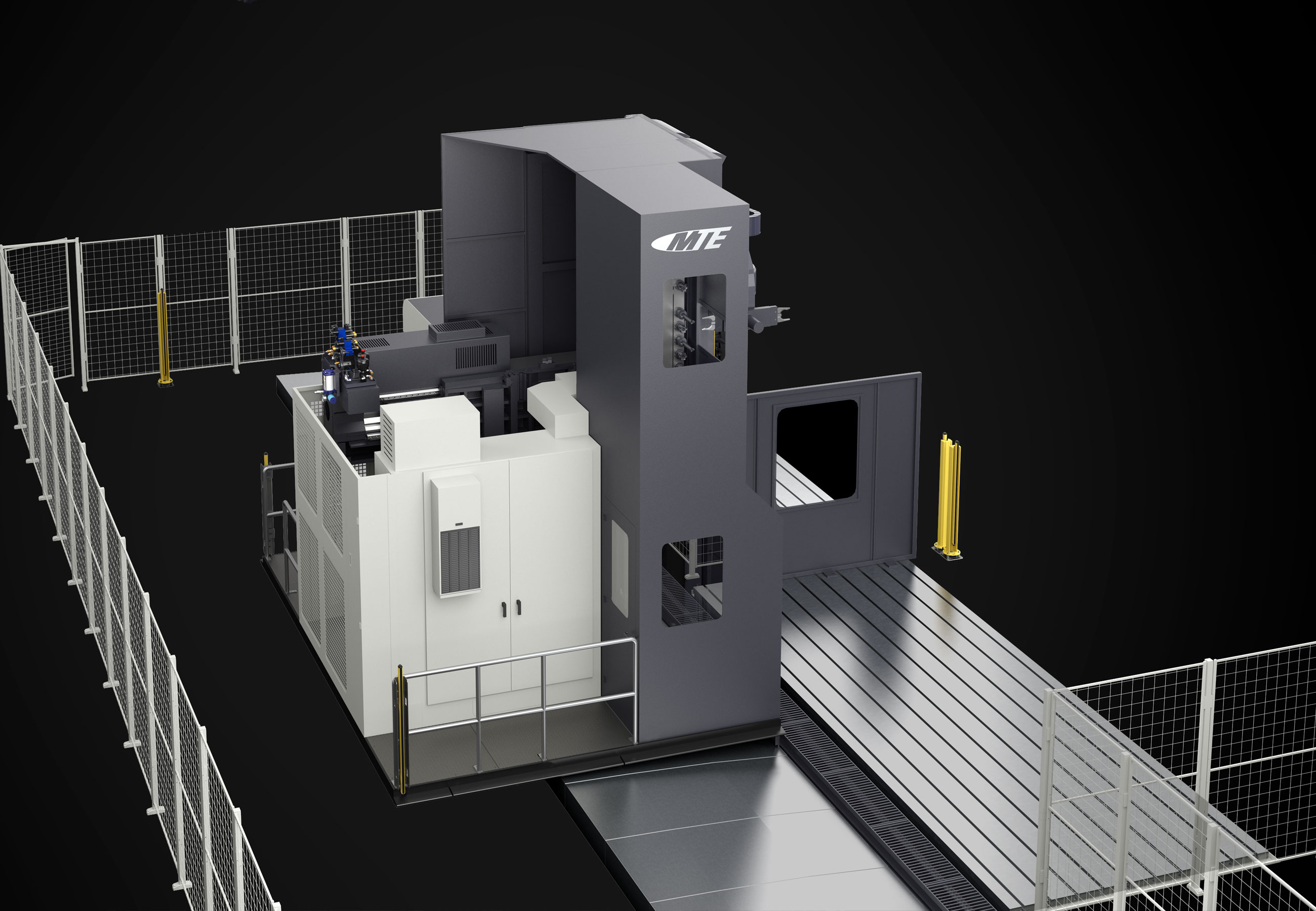

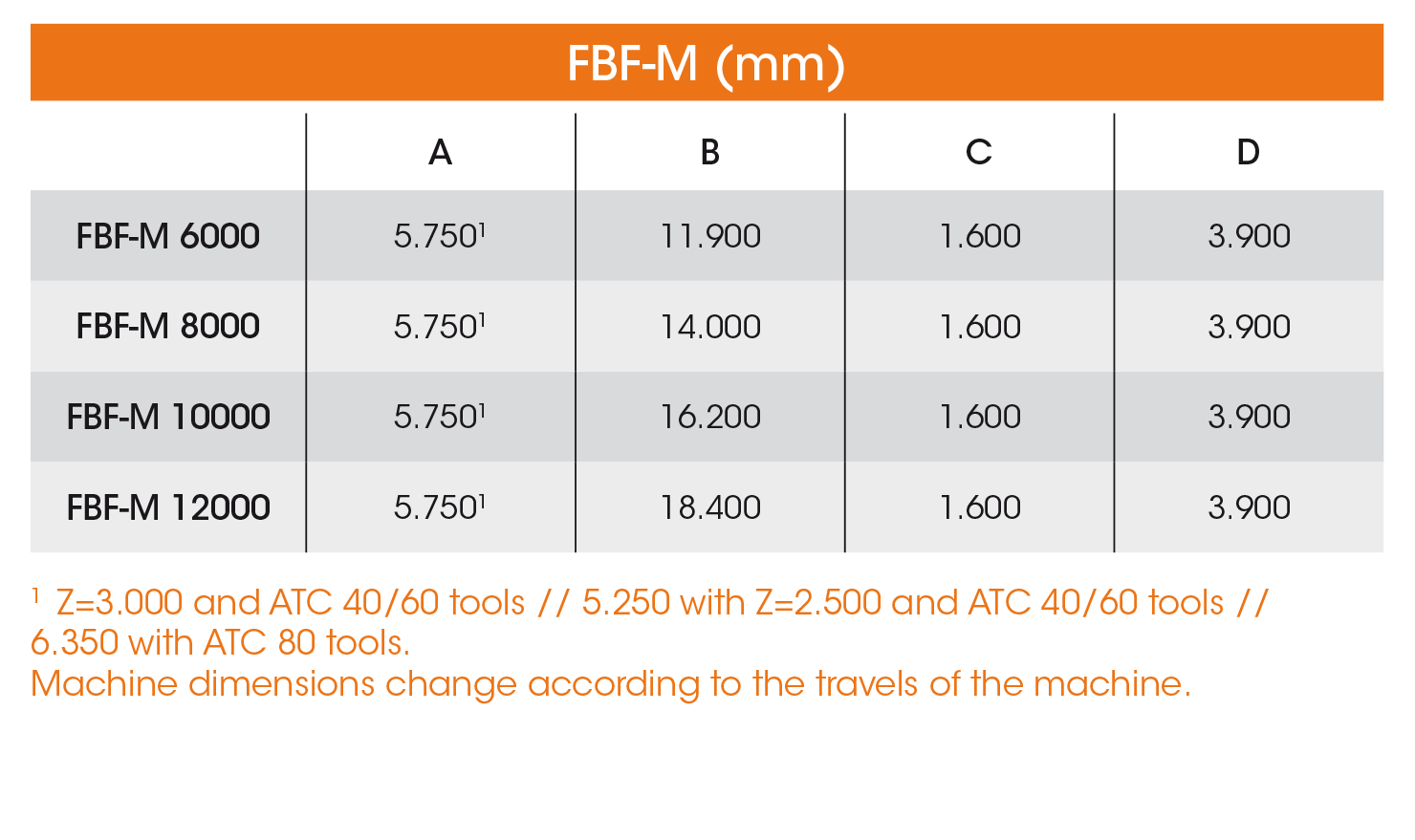

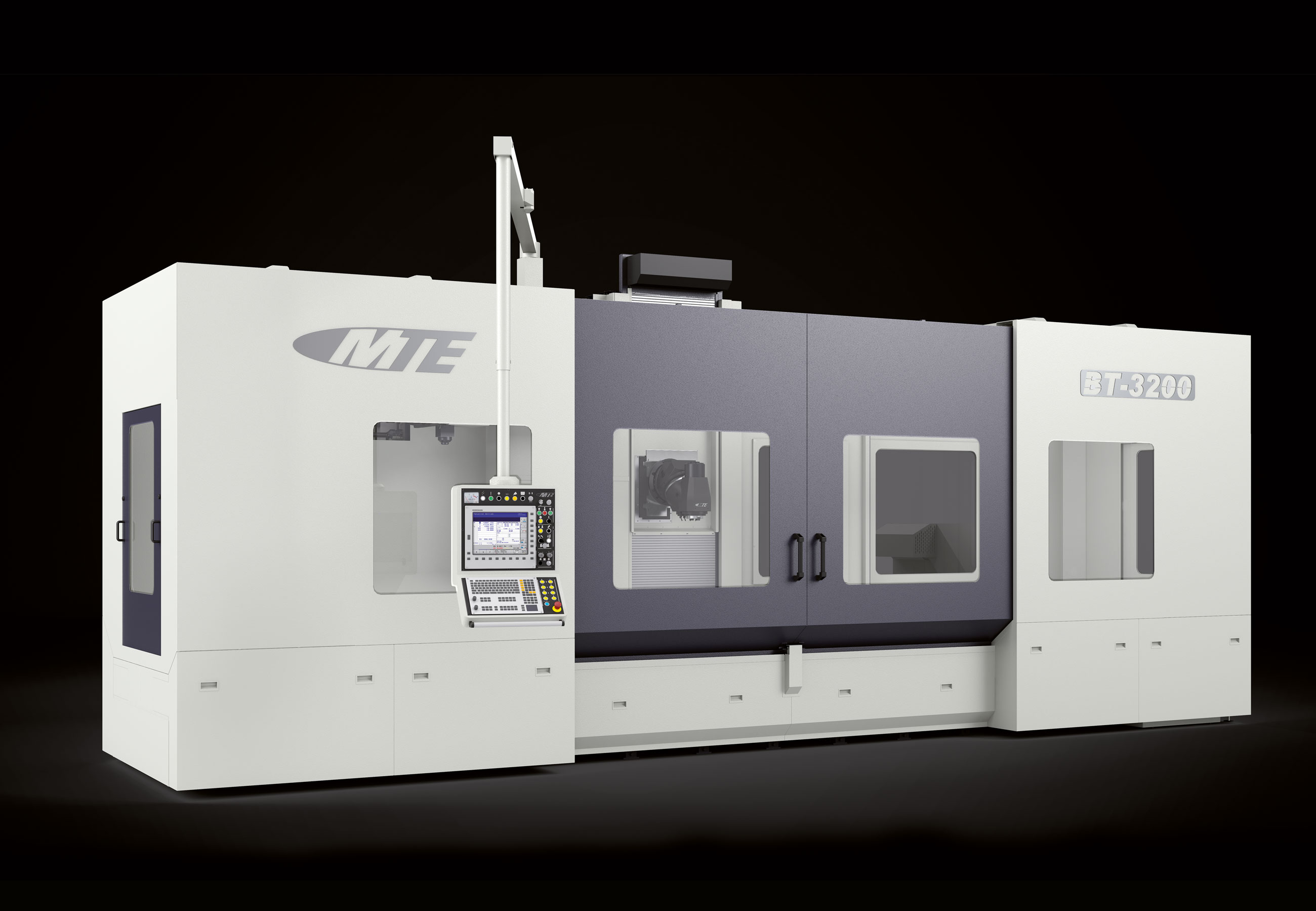

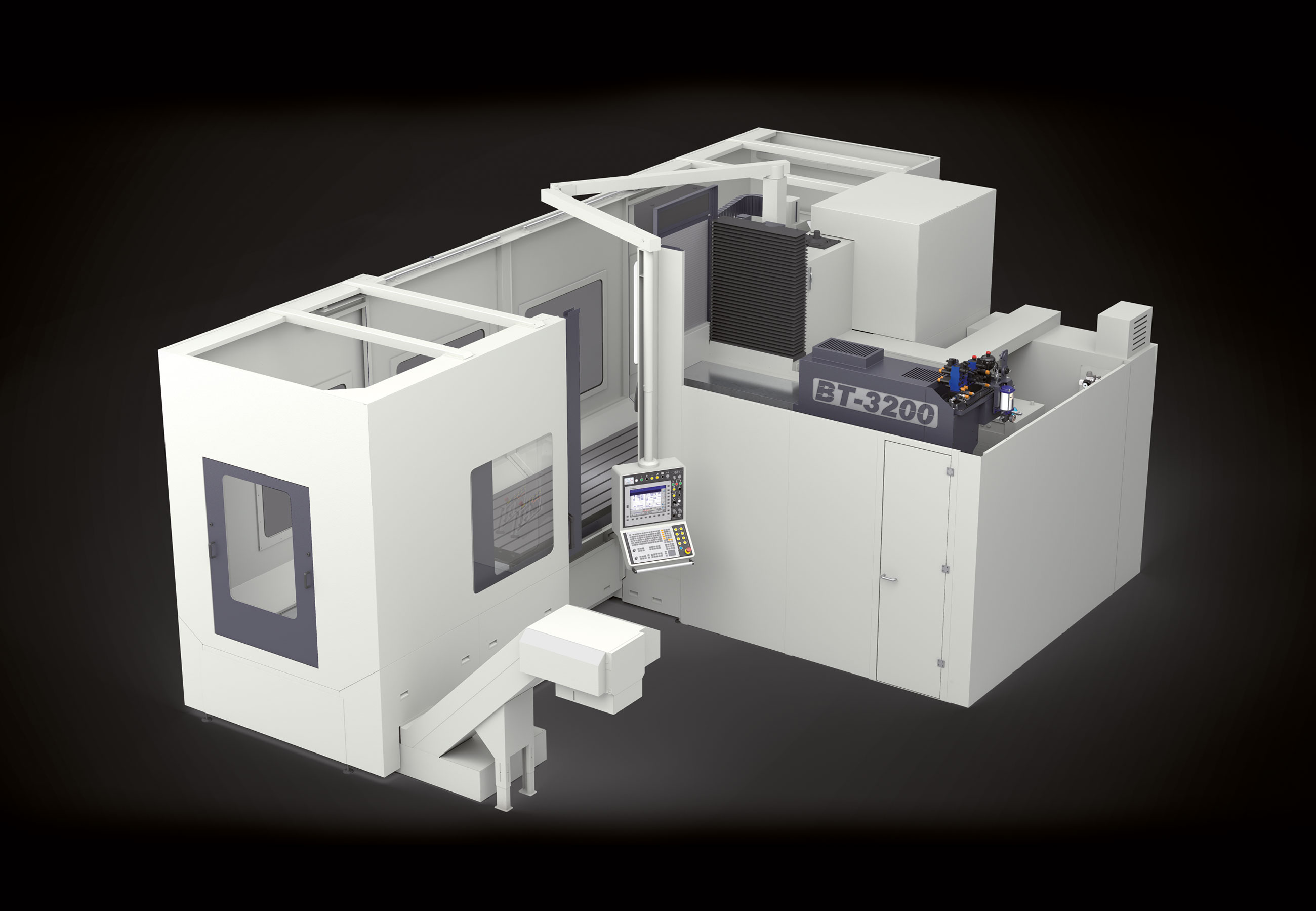

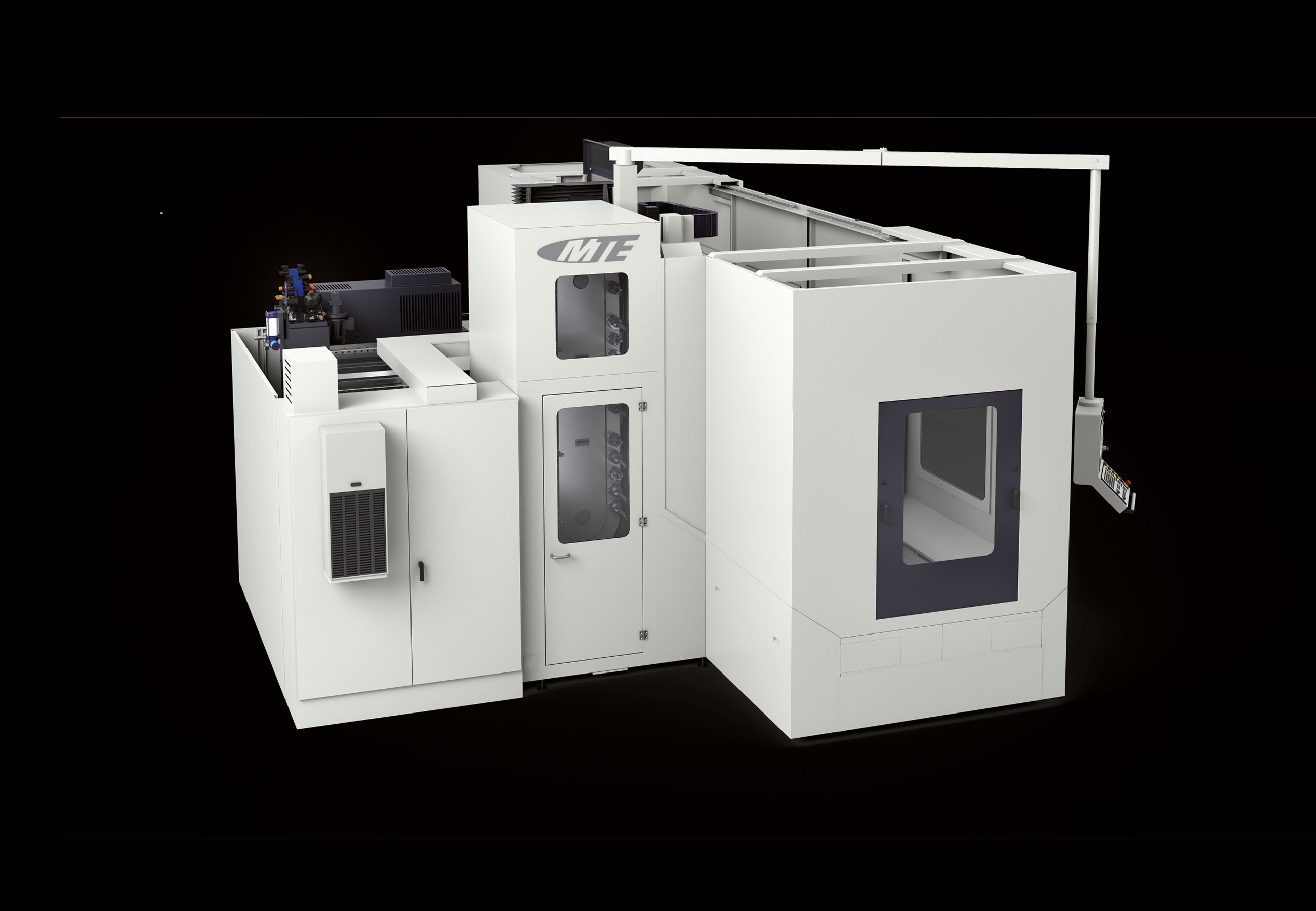

THE FBF-M SERIES WITH ITS EXTREMELY STABLE DESIGN IS PREDOMINANTLY USED FOR MECHANICAL ENGINEERING APPLICATIONS.

The series has fully automatic head changing systems with up to 4 different milling heads, rotary and traveling tables and tool changers, as well as optional shuttle machining, offering practical and maximum flexibility in the high-precision processing of extremely complex workpieces. They are used also for the processing of medium-sized and heavy workpieces with a vertical travel of up to 3,000 mm.

In some cases the machine is even used to process complex large tool moulds in high strength-to-density ratio materials.

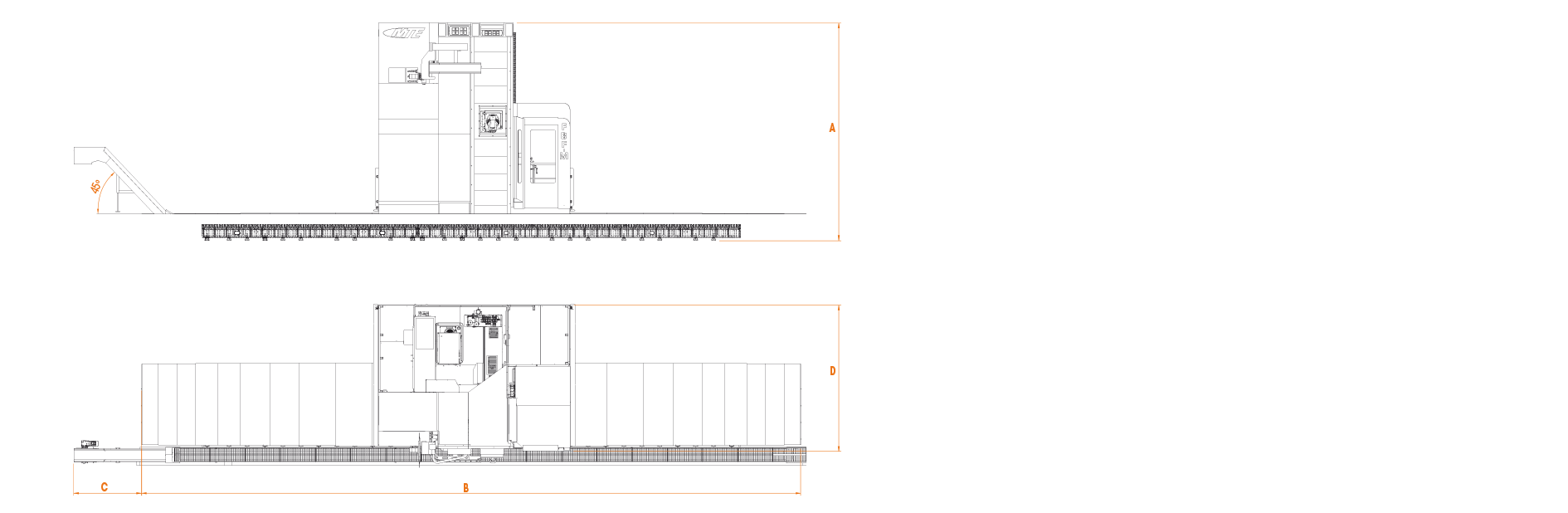

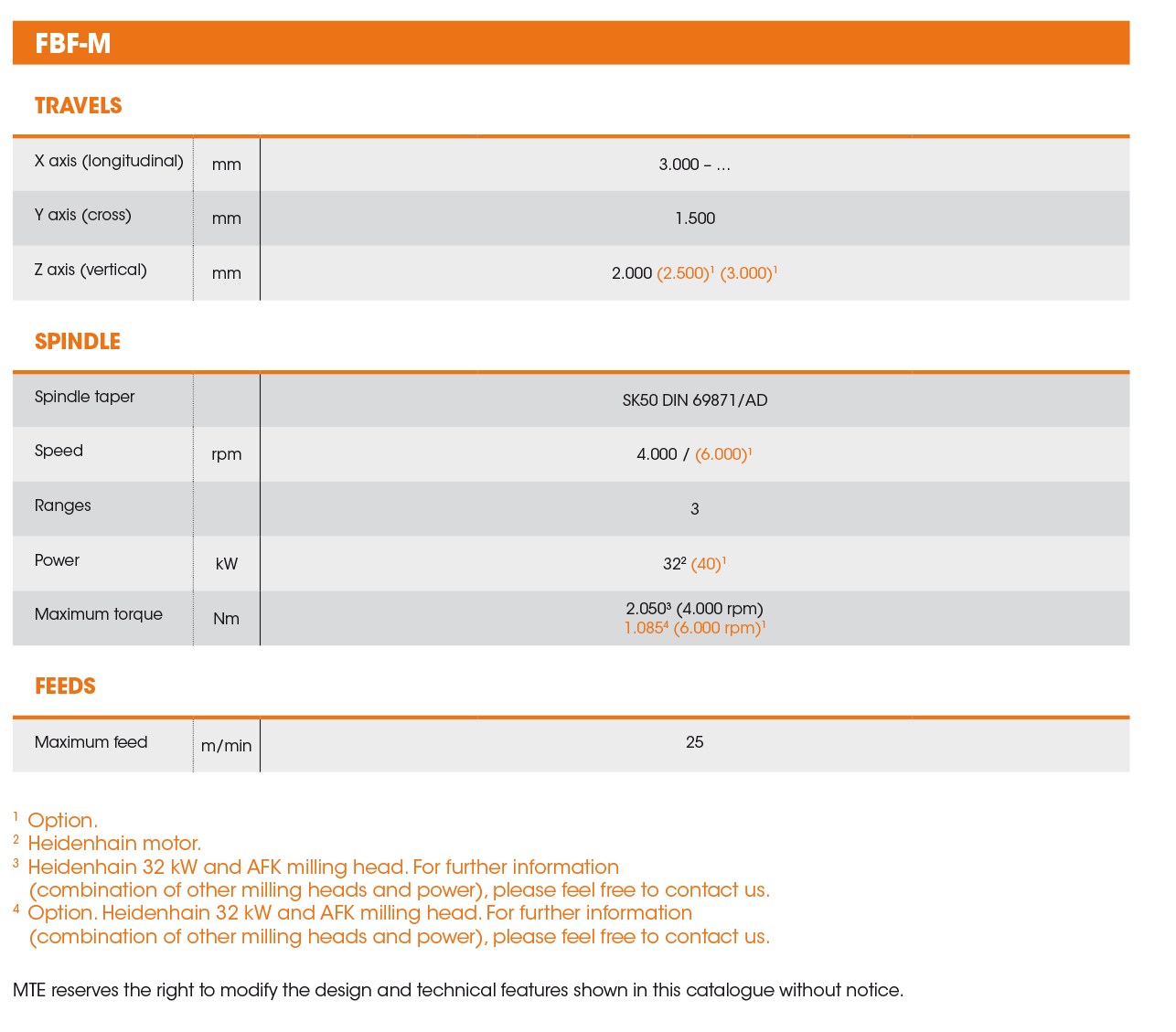

X = 4.000 – 36.000 mm

Y = 1.500 mm

Z = 2.000 – 3.000 mm

Y = 1.500 mm

Z = 2.000 – 3.000 mm

TECHNICAL FEATURES

FLOOR TYPE MILLING MACHINES

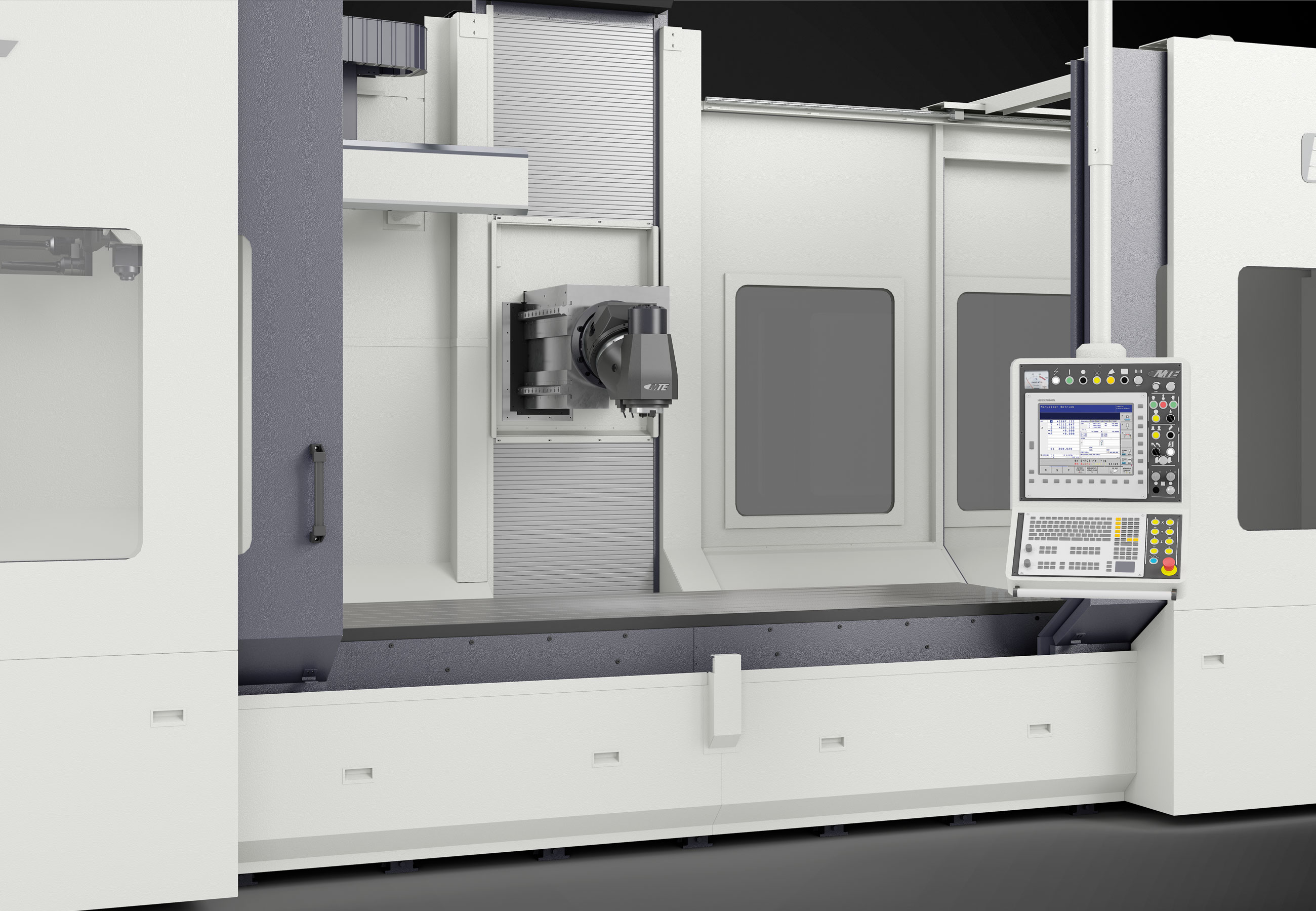

STANDARD EQUIPMENT

STANDARD EQUIPMENT FOR FBF-M MODEL FLOOR TYPE MILLING MACHINES.

- Three ranges cooled gearbox

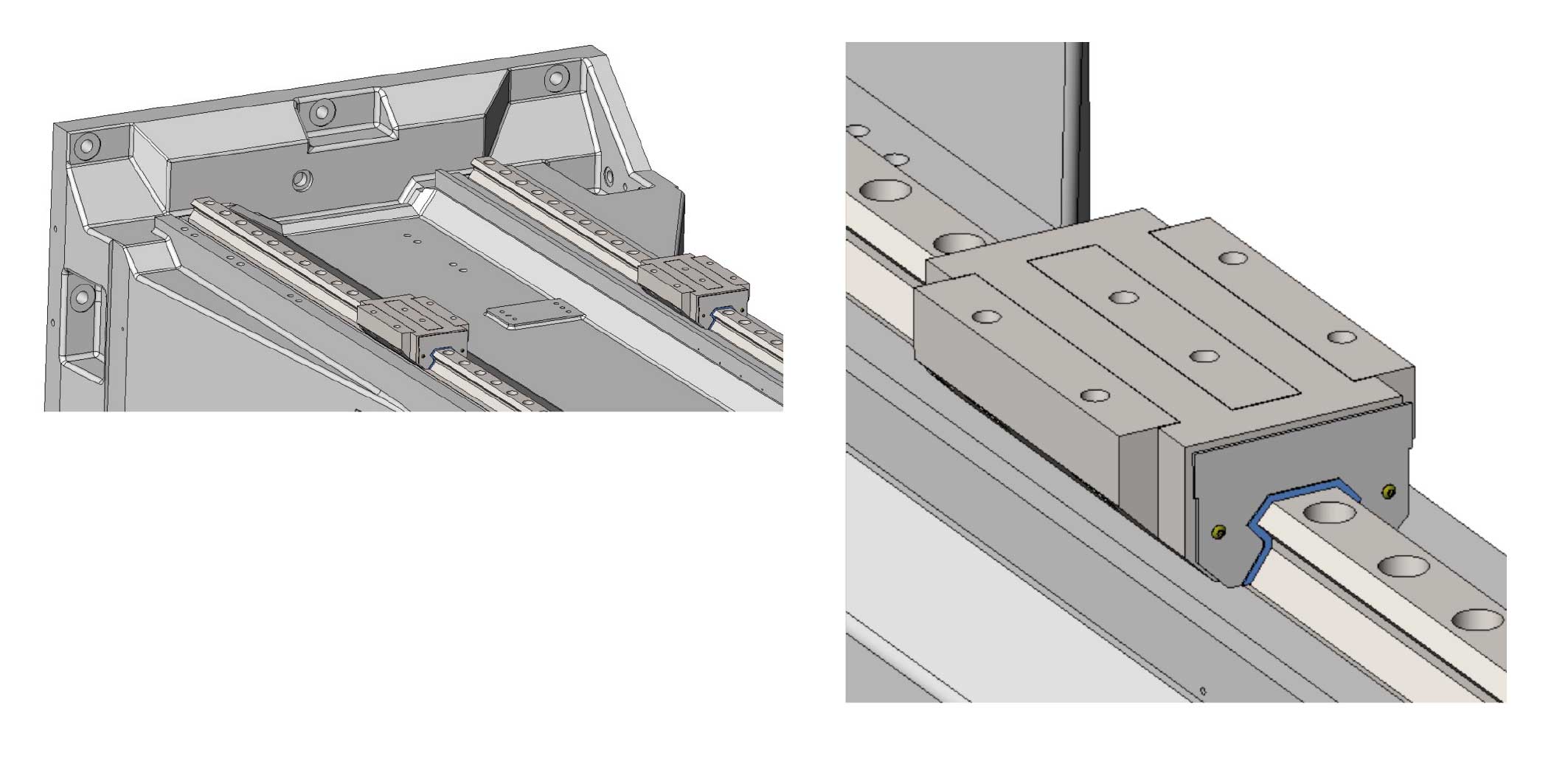

- INA linear guiding system

- Manual cooled milling head 4.000 rpm (MFK)

- Heidenhain CNC TNC 640

- Heidenhain direct pressurized linear scales

- Electronic handwheel

- Integrated security system (PILZ)

- Operator cabine with CNC control panel

- Perimetral closing according to CE standard

- Automatic lubrication system

- External coolant equipment

- Electrical cabinet cooling unit

- Hydraulic counterbalance system

- Working lights

- Levelling elements

- Air, power and ethernet connectors inside the cabin

OPTIONAL EQUIPMENT

OPTIONAL EQUIPMENT FOR FBF-M MODEL

- Manual cooled milling head 6.000 rpm (MFK)

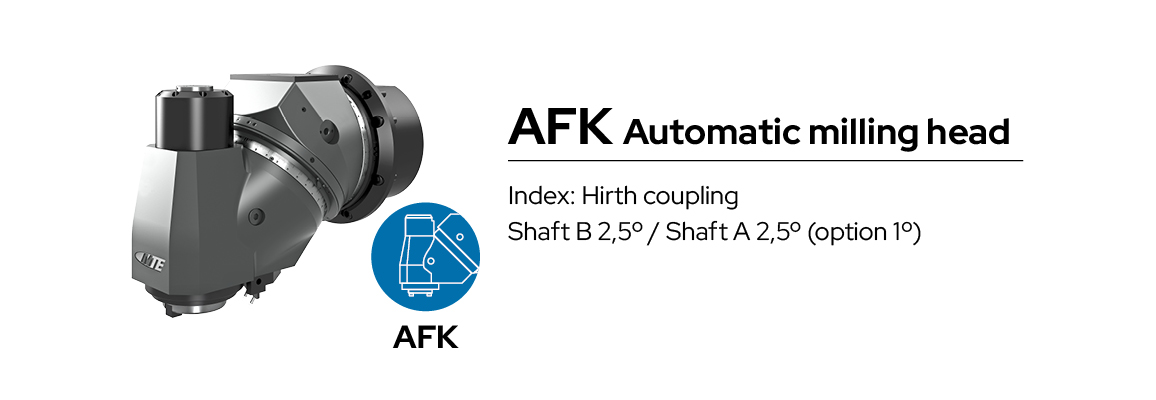

- Automatic cooled milling head 4.000/6.000 rpm 2,5°x2,5° (AFK)

- Automatic cooled milling head 4.000/6.000 rpm 2,5°x1° (AFK)

- Automatic cooled stepless milling head

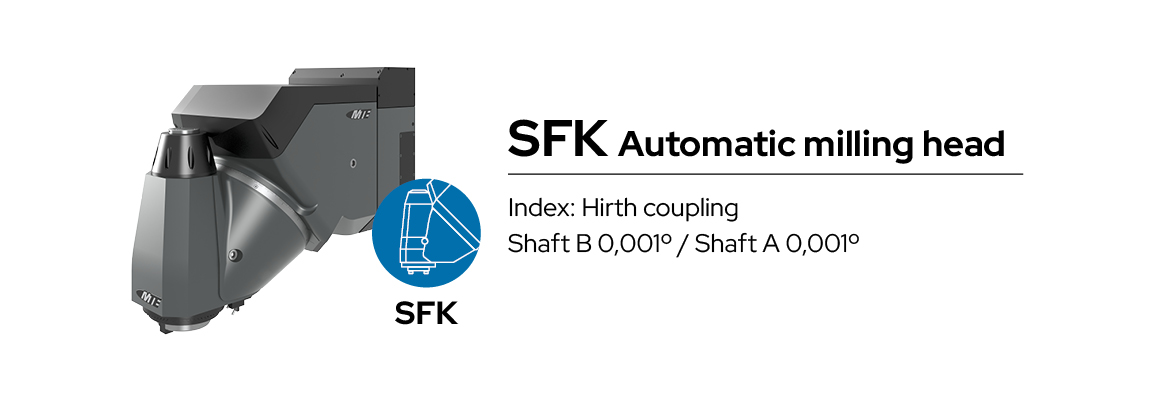

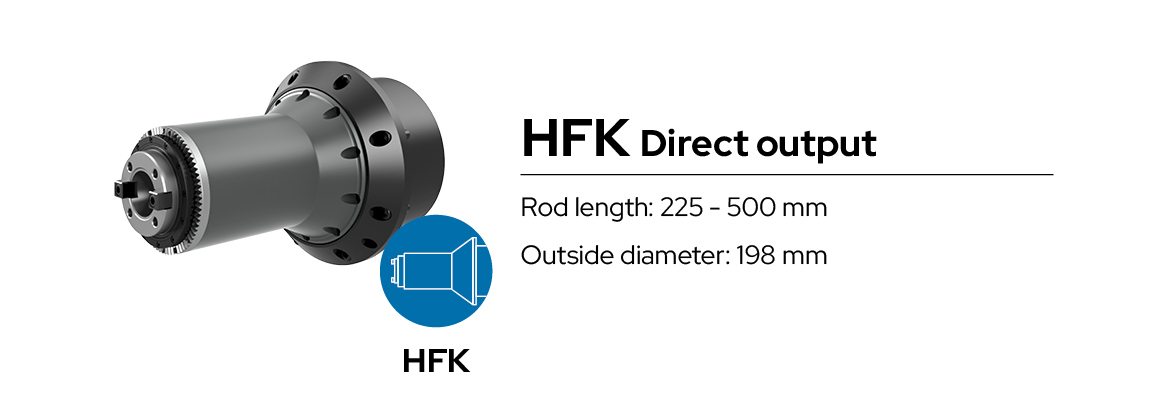

4.000/6.000 rpm 0,001° x 0,001° (SFK) - Direct spindle 4.000 rpm (HFK)

- Different CNC available: Siemens, Fanuc and Fagor

- 19 inches CNC screen

- Second control panel

- Wireless handwheel

- Teleservice

- Random vertical tool changer 24 tools

- Chain type horizontal / vertical tool changer

Number of tools: 40, 60, 80.

- Advanced tool magazine management

- Chip conveyor

- Coolant through the spindle 20/50 bar with filter paper system

- Magnetic drum / Oil band skimmer + micro-oxygen / Frequency controller for the motor

- Air through the spindle / Through outside nozzles

- Coolant pistols

- Fourth axis rotary tables

- Tools & piece probes (M&H, Heidenhain and Renishaw Brankamp CMS (Collision Monitoring System)

- Pendular working function

- Vertical elevation operator platform

- Vertical/horizontal elevation operator platform

- MQL Systems

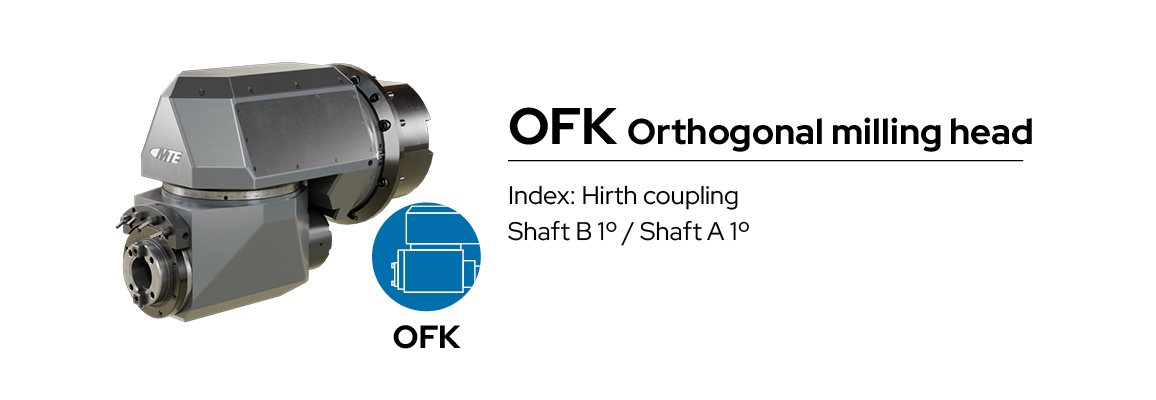

MILLING HEADS

LINEAR GUIDEWAY DETAIL

MTE | MILLING MACHINES

We’re big enough to develop innovative milling technologies for the challenging global markets and flexible enough, as an owner-managed company, to deliver a highly individual and personal customer experience

SITE MAP

CONTACT

MTE Machine Tool Engineering S.A.

Polígono Industrial, Parcela M-4.1

E – 20829 Itziar-Deba (Spain)

Tel: +34 943 60 63 83

info@mtemachine.com

www.mtemachine.com

Google Maps