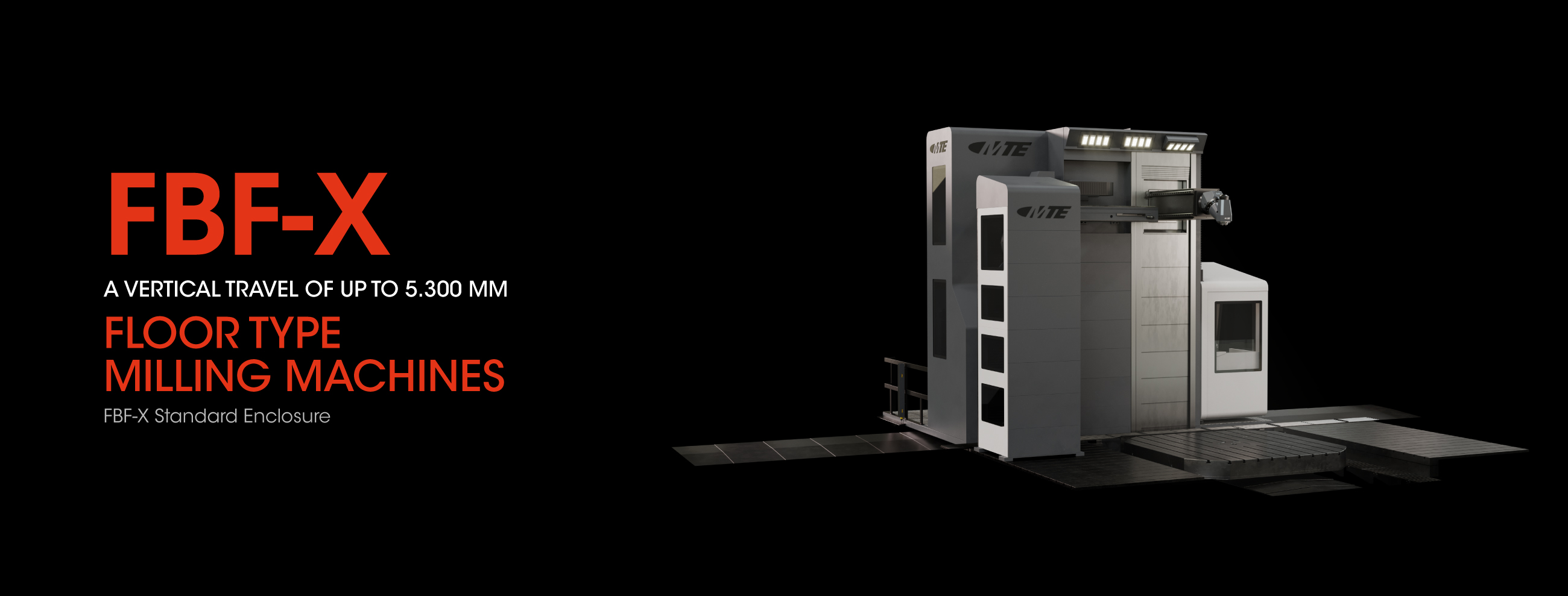

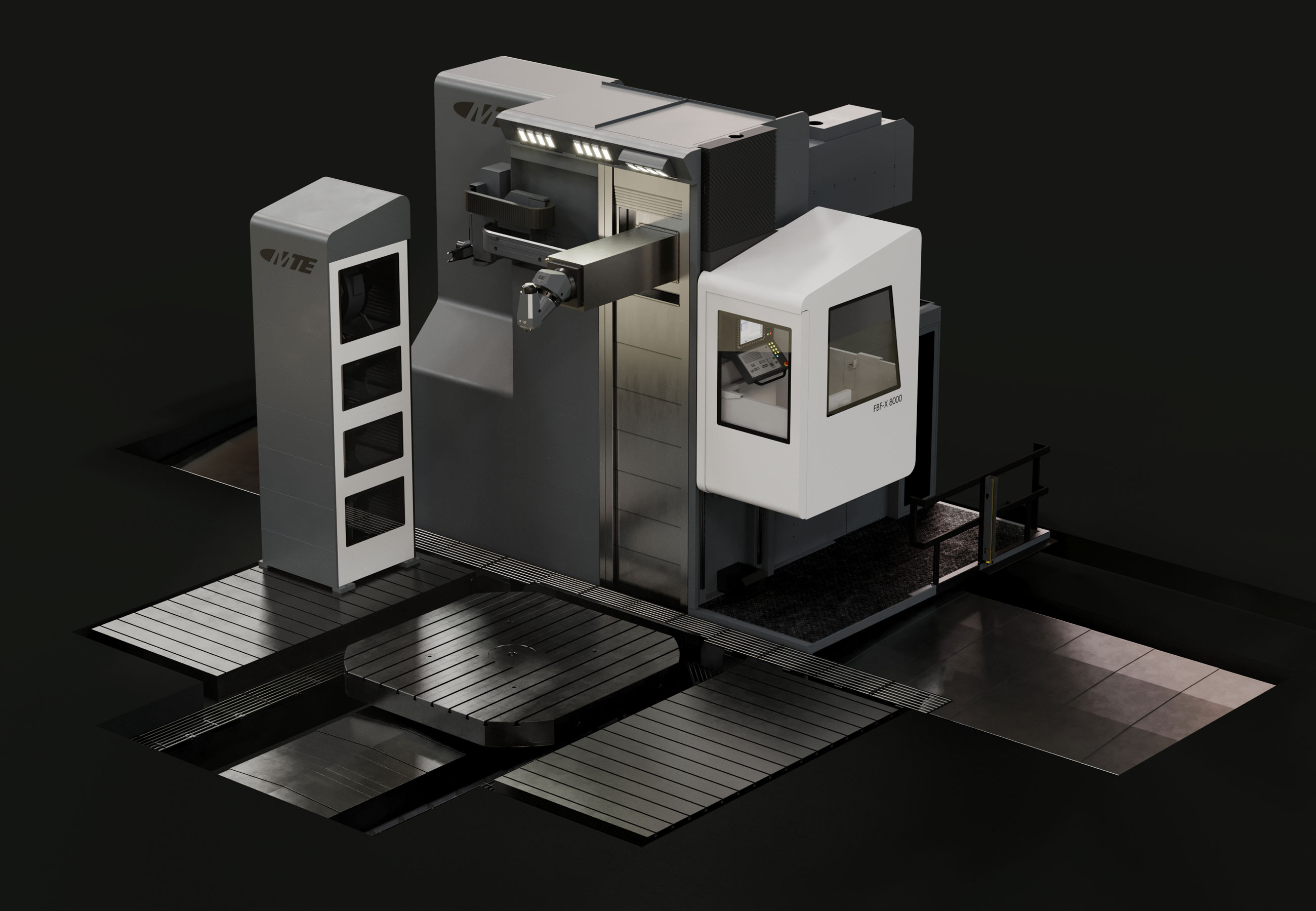

THE FBF-X SERIES WITH ITS EXTREMELY STABLE DESIGN IS PREDOMINANTLY USED FOR MECHANICAL ENGINEERING APPLICATIONS.

The FBF-X series brings together all the benefits of the travelling column range in a single machine with an even more robust design. In combination with size 100 guideways, the most demanding jobs are made possible and new machining heights can be reached. In this case, the vertical travel is up to 5.300 mm. Just as our machines are designed to achieve optimal performance, all the finishings are taken care of to the smallest detail.

X = 5.000 – 36.000 mm

Y = 3.500 – 5.300 mm

Z = 1.600 – 1.8000 mm

Y = 3.500 – 5.300 mm

Z = 1.600 – 1.8000 mm

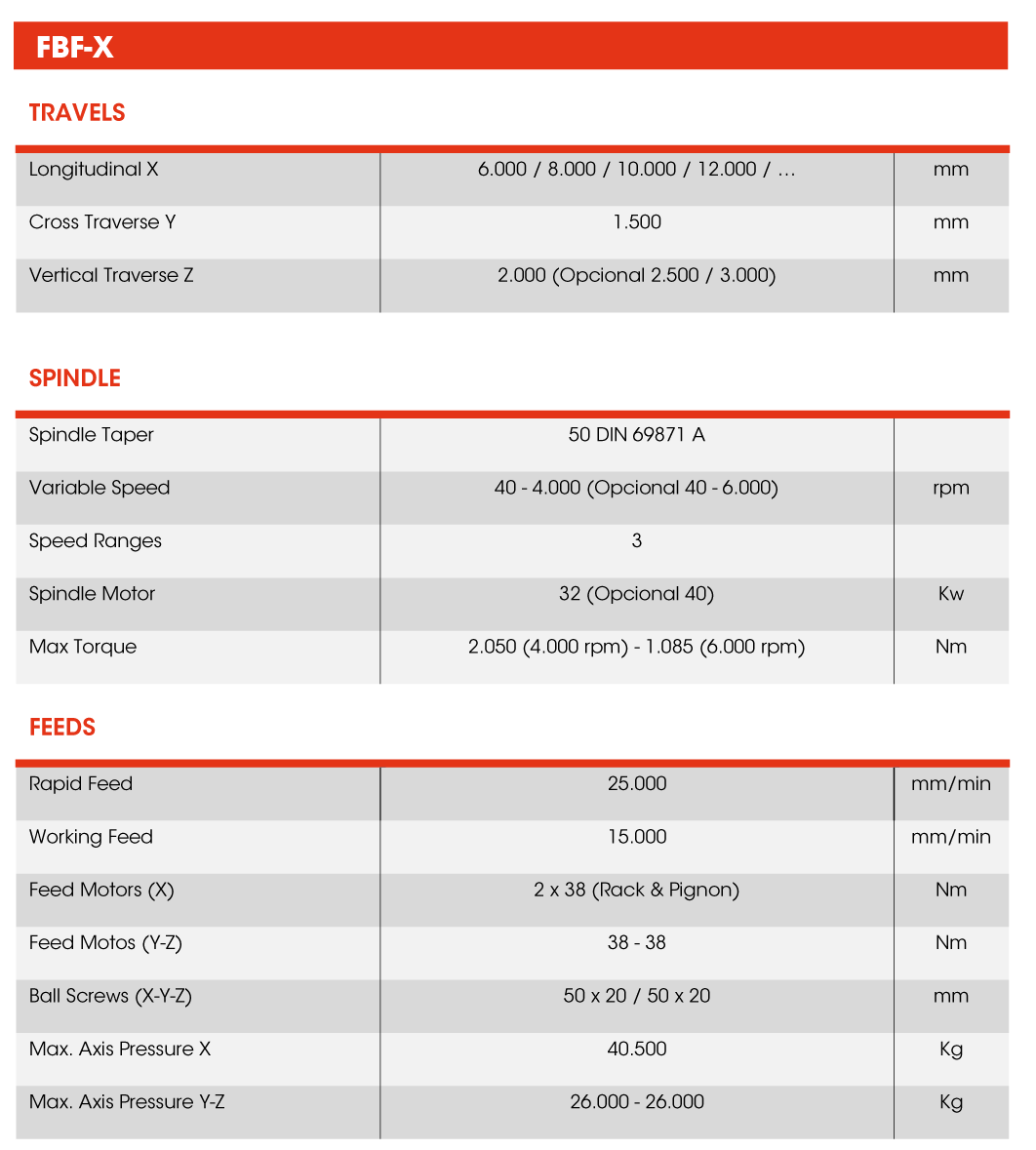

TECHNICAL FEATURES

FLOOR TYPE MILLING MACHINES

STANDARD EQUIPMENT

STANDARD EQUIPMENT FOR FBF-X MODEL FLOOR TYPE MILLING MACHINES.

- Three ranges cooled gearbox

- INA linear guiding system

- Manual milling head 4.000 rpm (MFK)

- Heidenhain CNC iTNC 530 HSCi / TNC 640

- Heidenhain direct pressurized linear scales

- Electronic handwheel

- Integrated security system (PILZ)

- Operator cabine with CNC control panel

- Perimetral closing according to CE standard

- Automatic lubrication system

- External coolant equipment

- Electrical cabinet cooling unit

- Hydraulic counterbalance system

- Working lights

- Levelling elements

- Air, power and ethernet connectors inside the cabin

OPTIONAL EQUIPMENT

OPTIONAL EQUIPMENT FOR FBF-M MODEL

- Manual milling head 6.000 rpm (MFK)

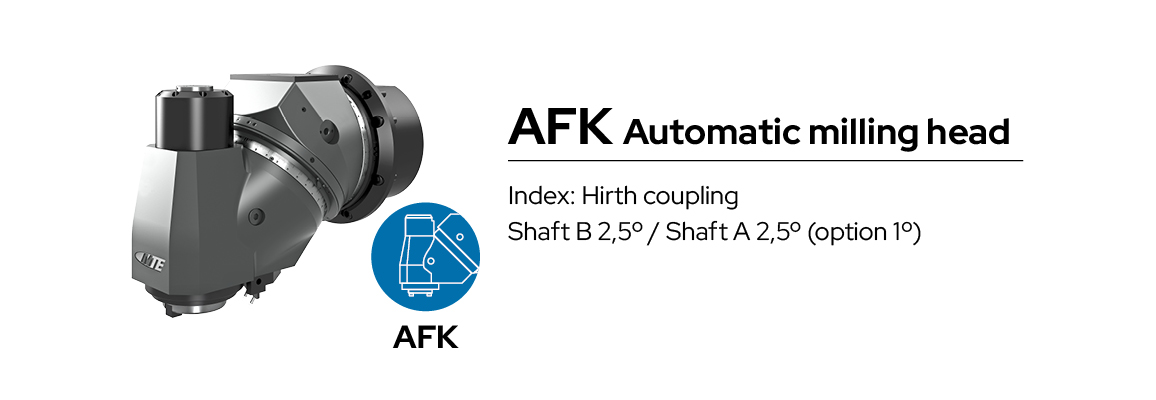

- Automatic milling head 4.000/6.000 rpm 2,5°x2,5° (AFK)

- Automatic milling head 4.000/6.000 rpm 2,5°x1° (AFK)

- Automatic continuous milling head

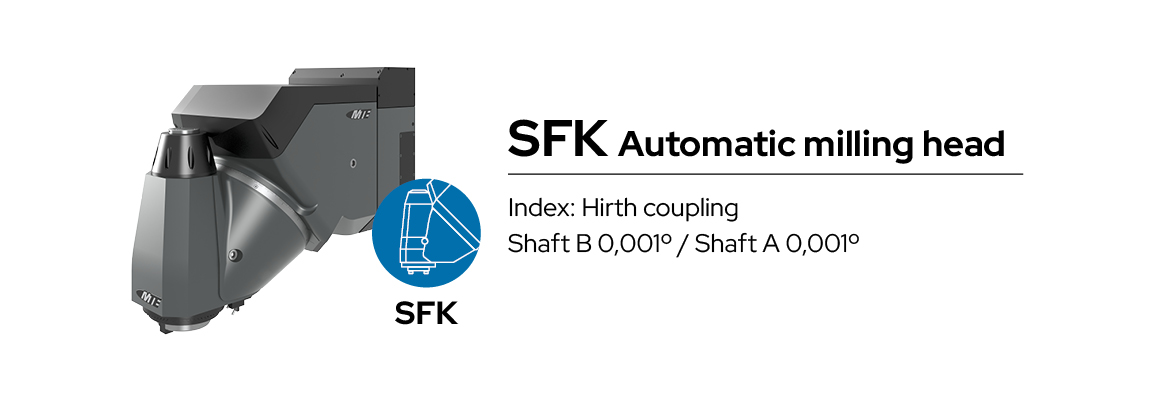

4.000/6.000 rpm 0,001° x 0,001° (SFK) - Direct spindle 4.000 rpm (HFK)

- Different CNC available: Siemens, Fanuc and Fagor

- 19 inches CNC screen

- Second control panel

- Wireless handwheel

- Teleservice

- Random vertical tool changer 24 tools

- Chain type horizontal / vertical tool changer

Number of tools: 40, 60, 80.

- Advanced tool magazine management

- Chip conveyor

- Coolant through the spindle 20/50 bar with filter paper system

- Magnetic drum / Oil band skimmer + micro-oxygen / Frequency controller for the motor

- Air through the spindle / Through outside nozzles

- Coolant pistols

- Fourth axis rotary tables

- Tools & piece probes (M&H, Heidenhain and Renishaw Brankamp CMS (Collision Monitoring System)

- Pendular working function

- Vertical elevation operator platform

- Vertical/horizontal elevation operator platform

- MQL Systems

Note: all 6.000 rpm milling heads are cooled. Cooled head optional at 4.000 rpm.

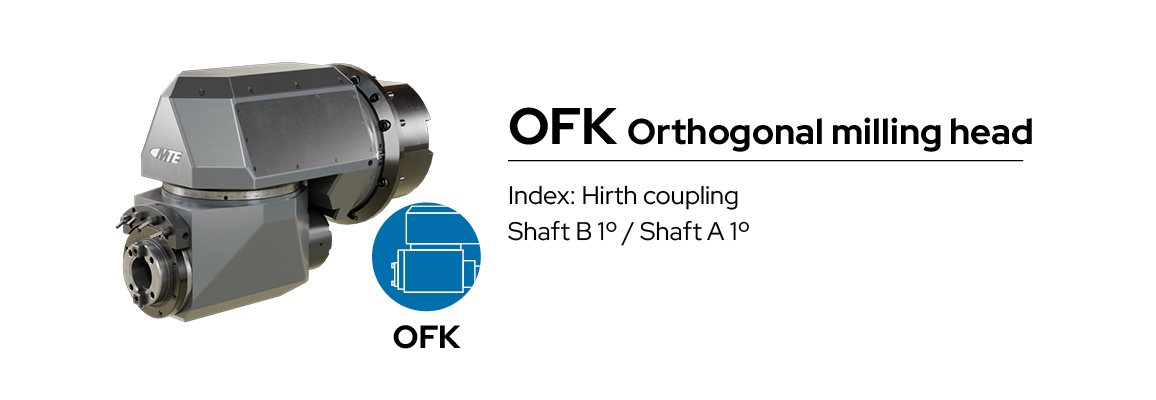

MILLING HEADS

MTE | MILLING MACHINES

We’re big enough to develop innovative milling technologies for the challenging global markets and flexible enough, as an owner-managed company, to deliver a highly individual and personal customer experience

SITE MAP

CONTACT

MTE Machine Tool Engineering S.A.

Polígono Industrial, Parcela M-4.1

E – 20829 Itziar-Deba (Spain)

Tel: +34 943 60 63 83

info@mtemachine.com

www.mtemachine.com

Google Maps