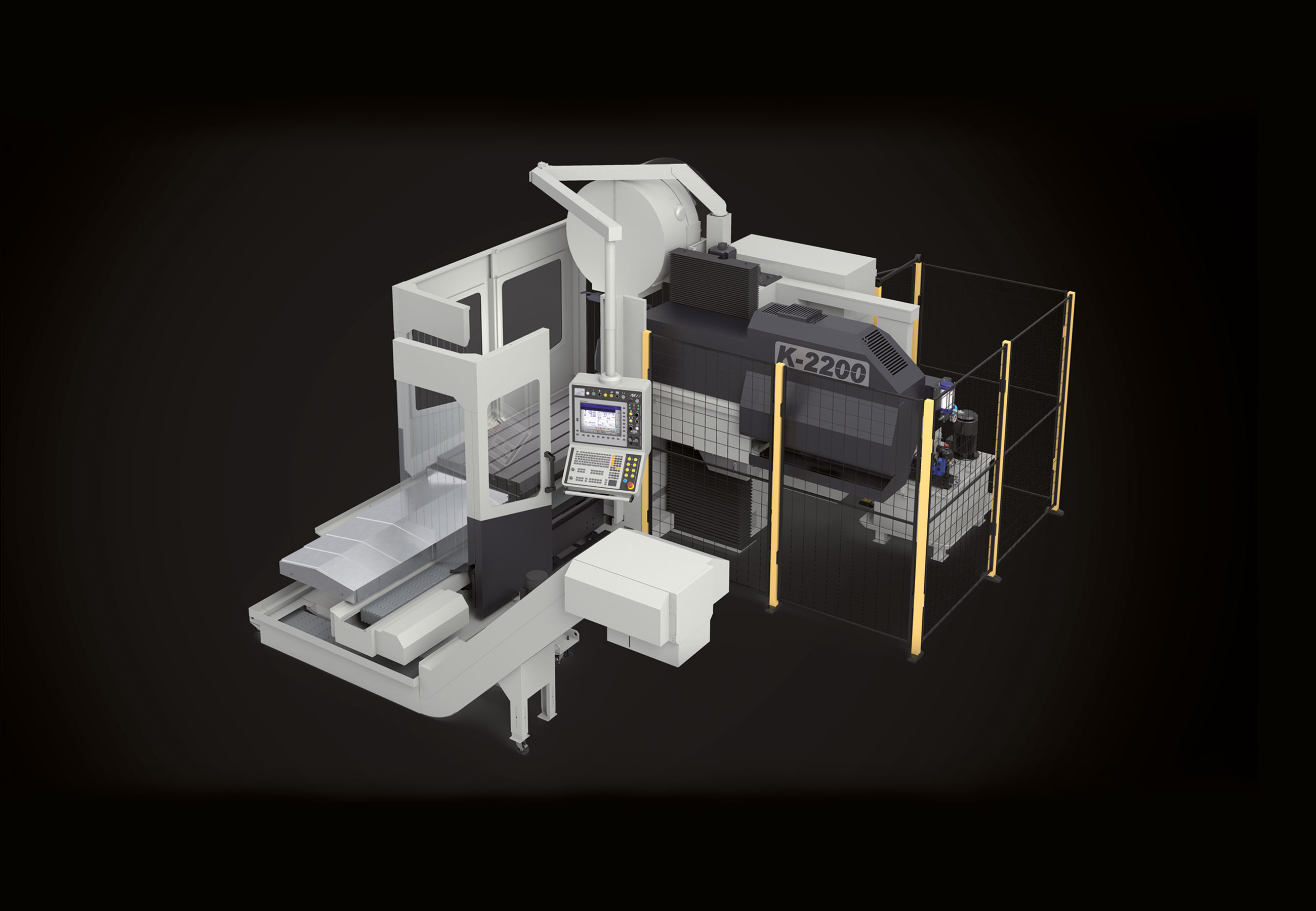

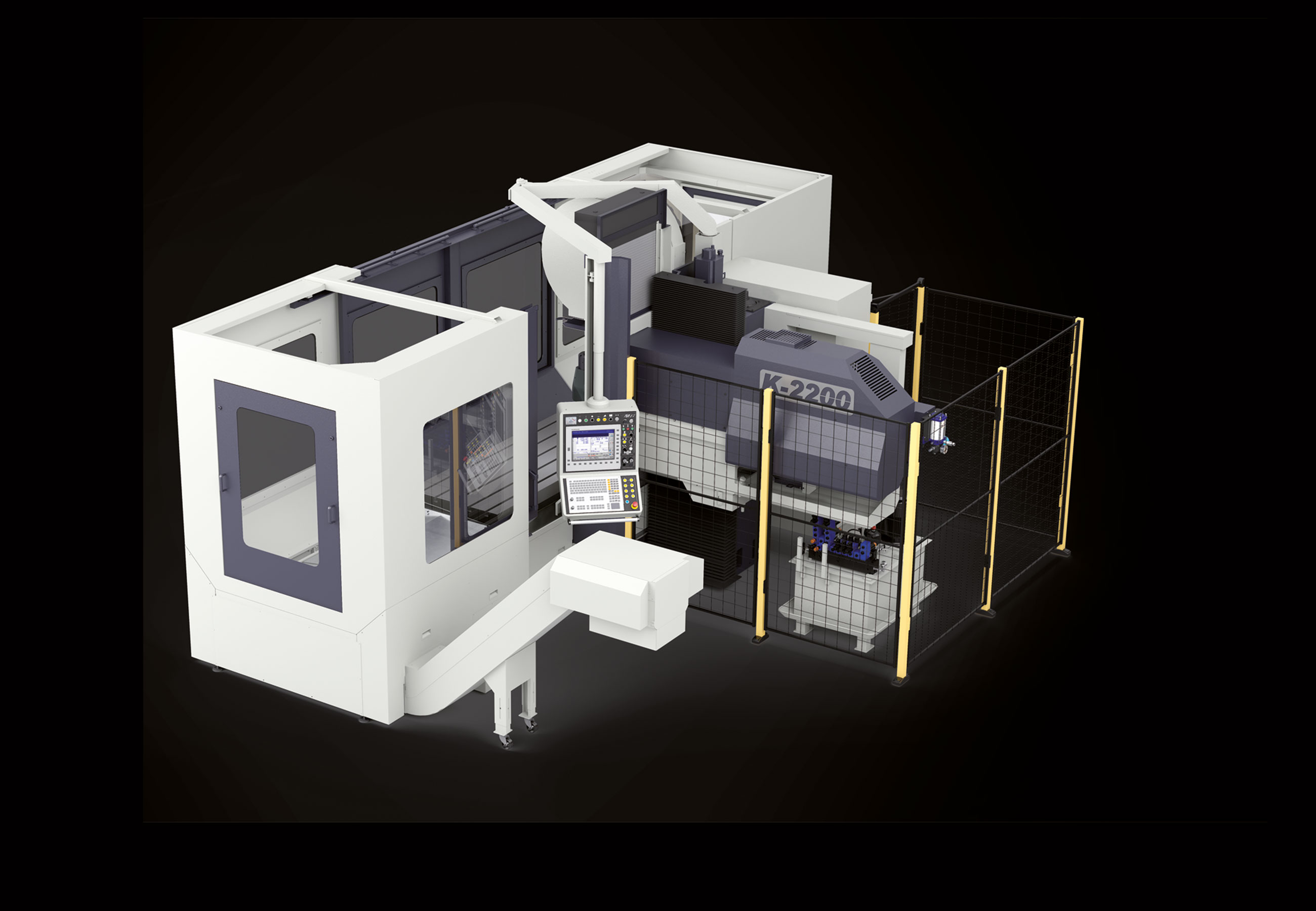

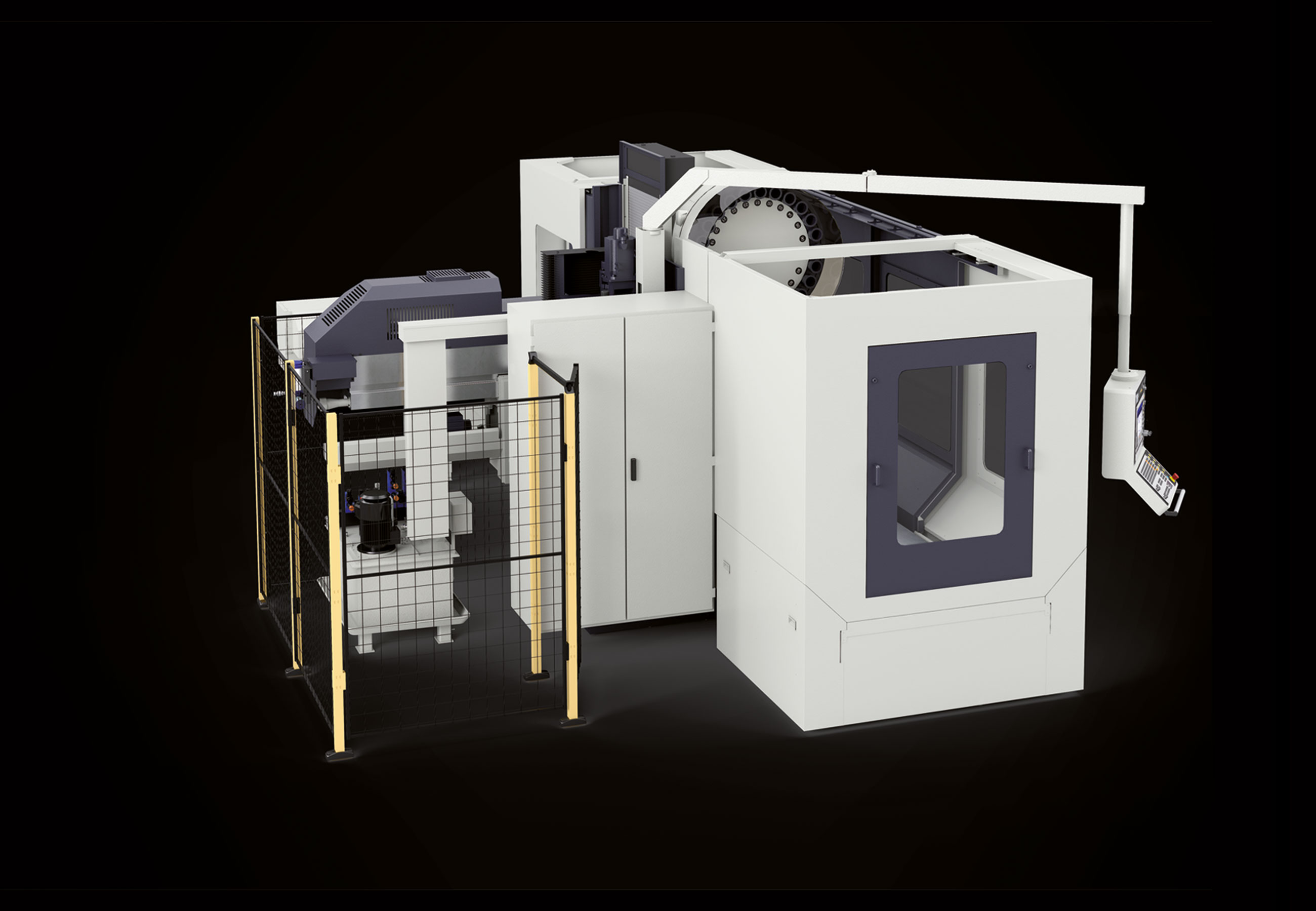

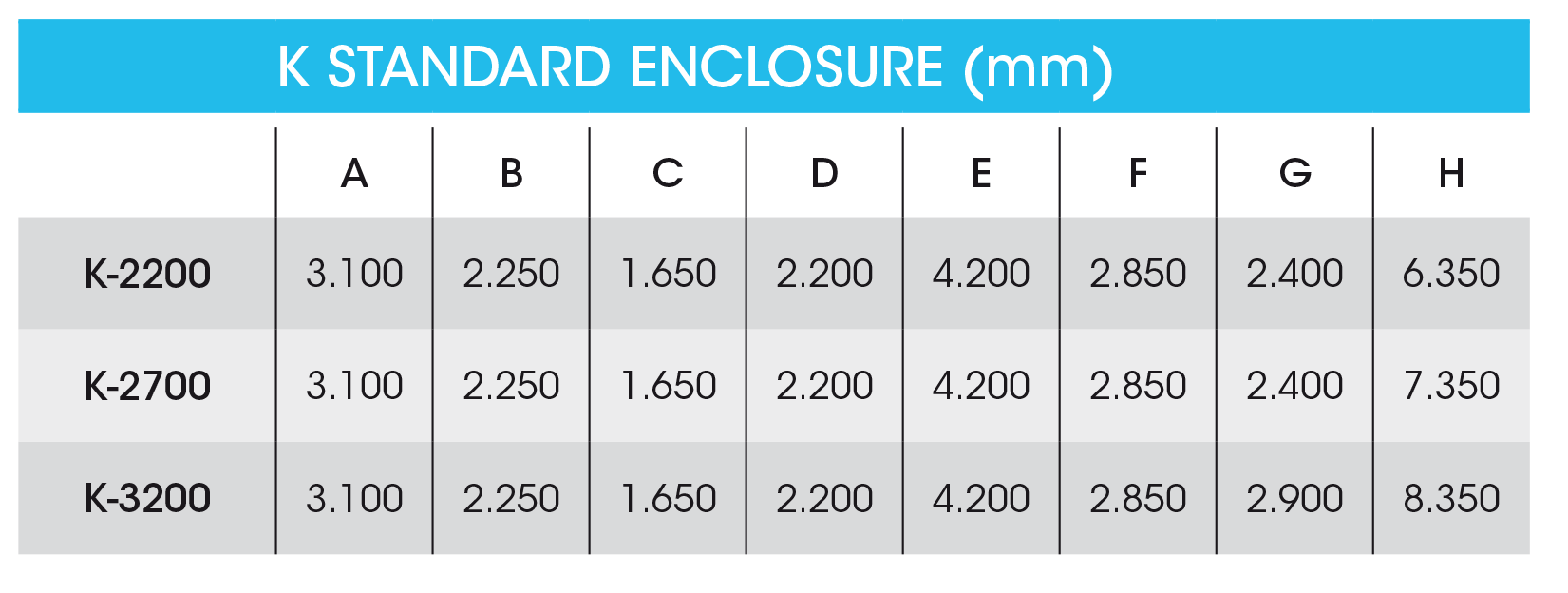

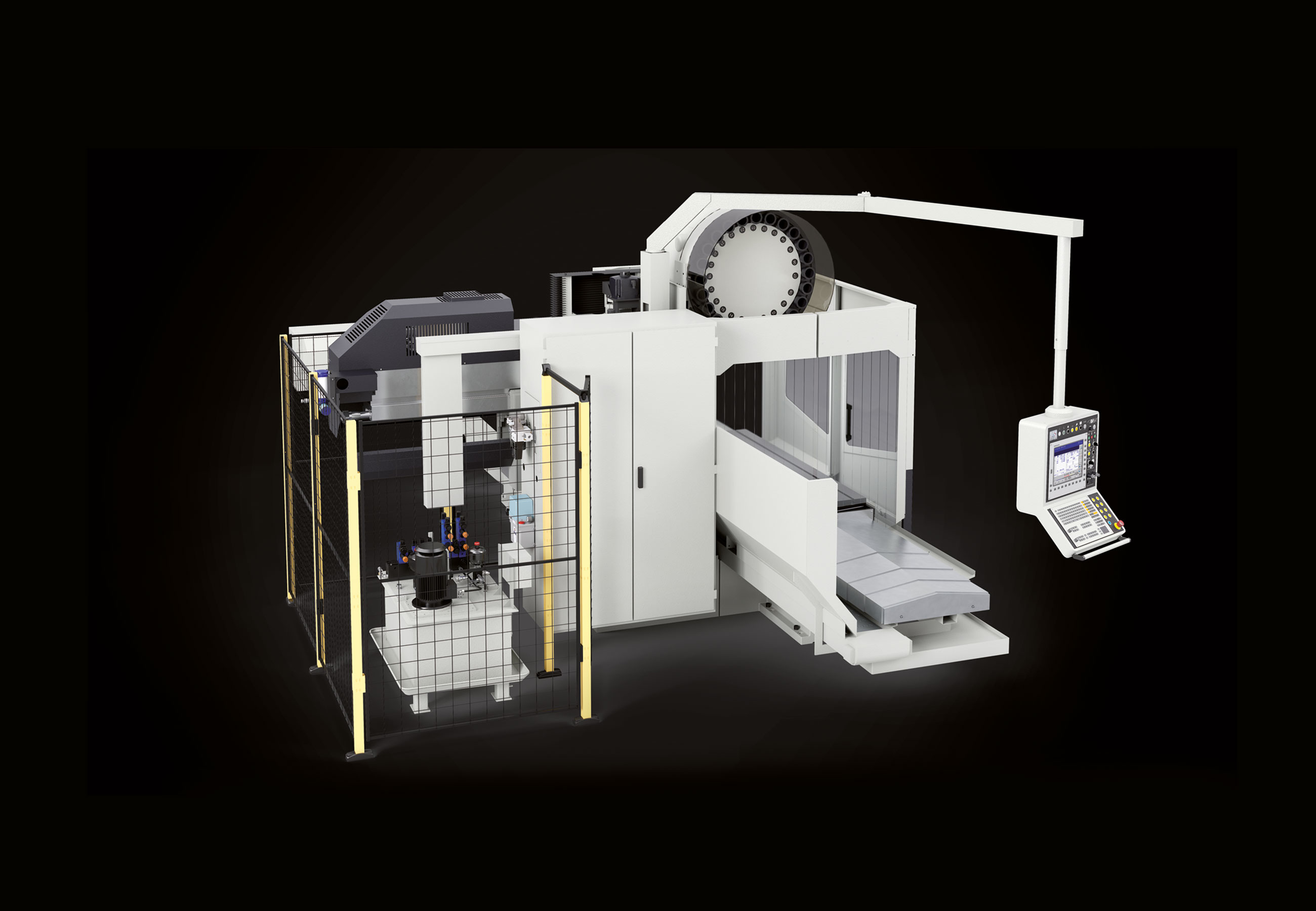

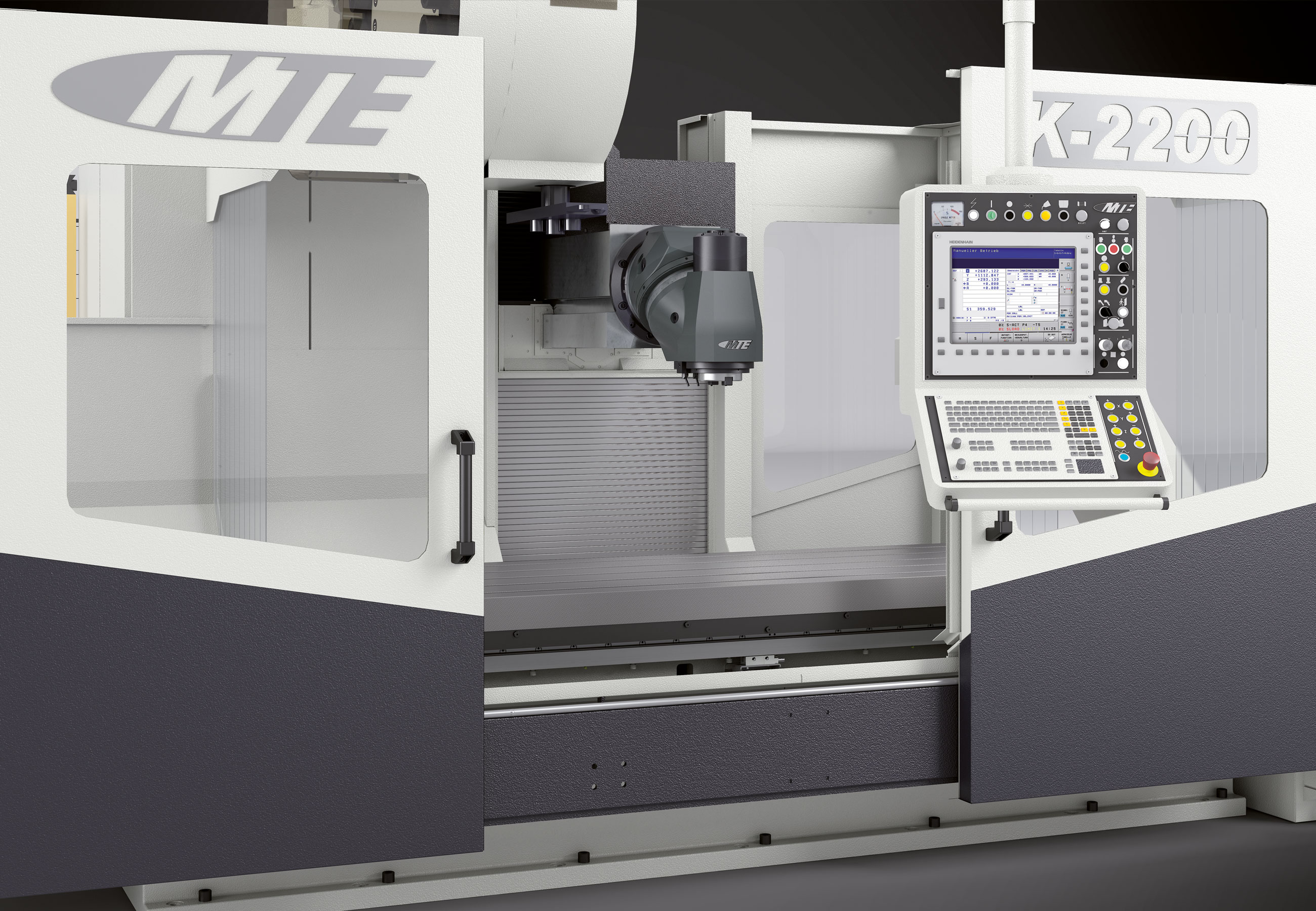

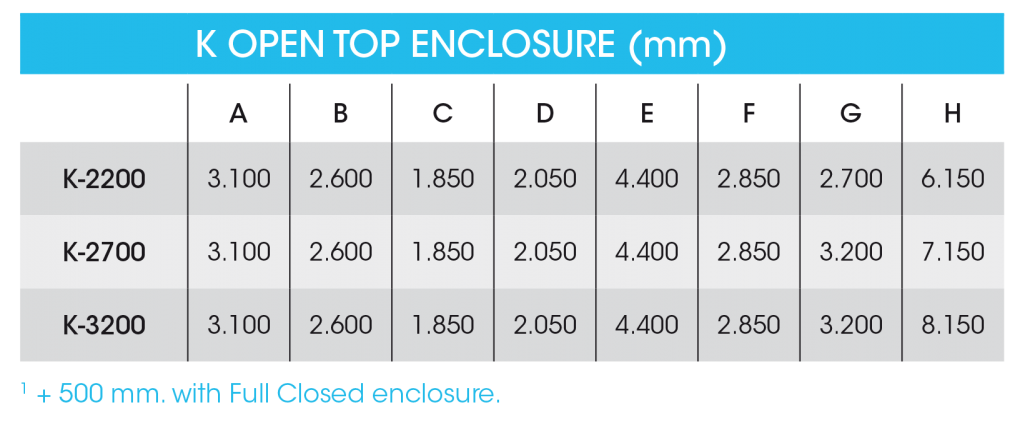

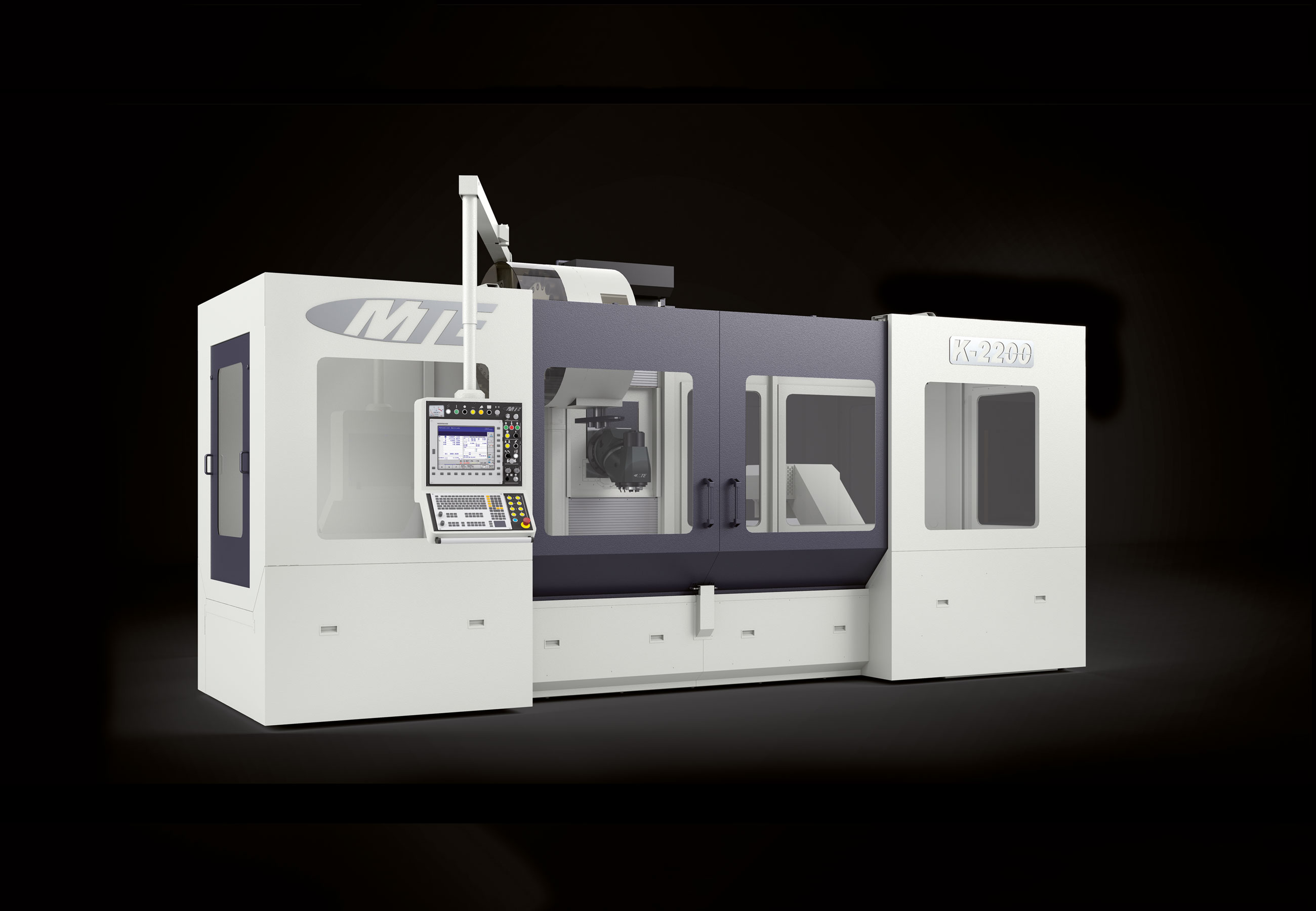

THE K SERIES IS USED FOR TOOL MAKING, AND IN THE MECHANICAL ENGINEERING AND STEEL CONSTRUCTION INDUSTRIES FOR PROCESSING MEDIUM-SIZED, COMPACT WORKPIECES.

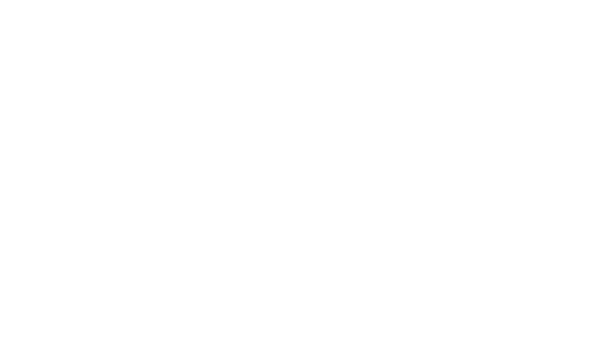

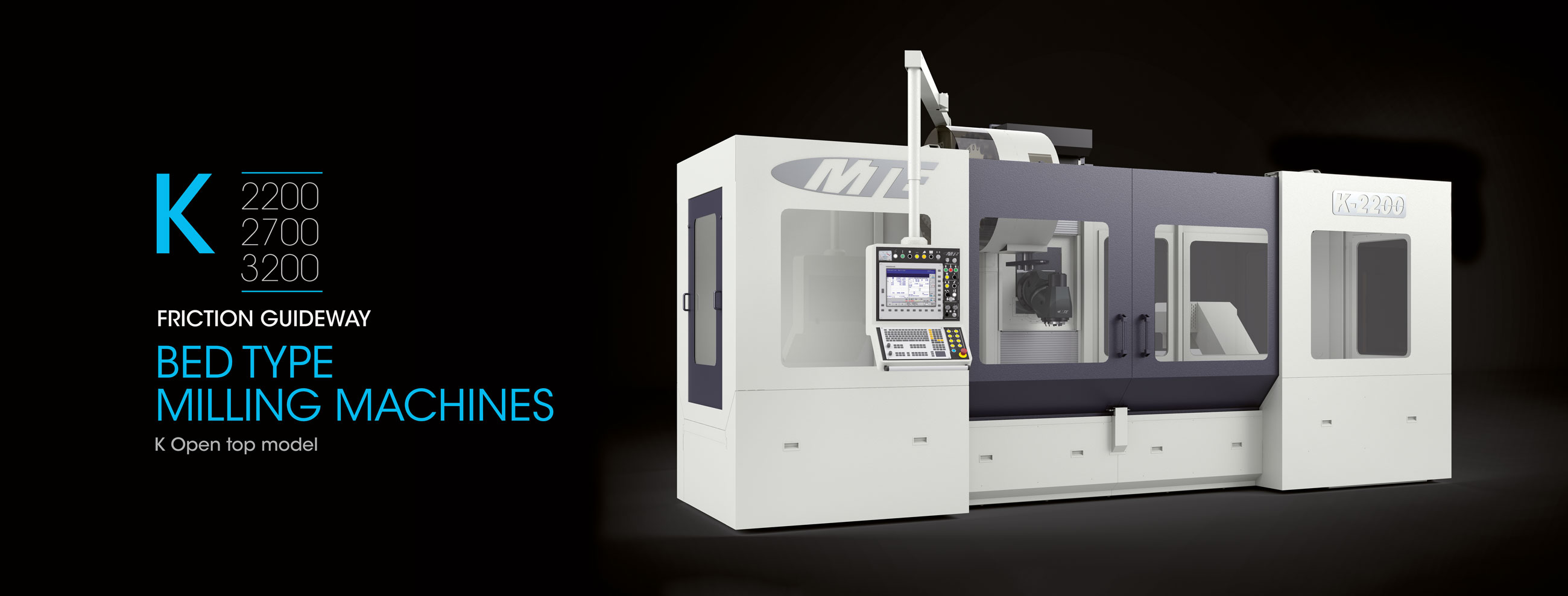

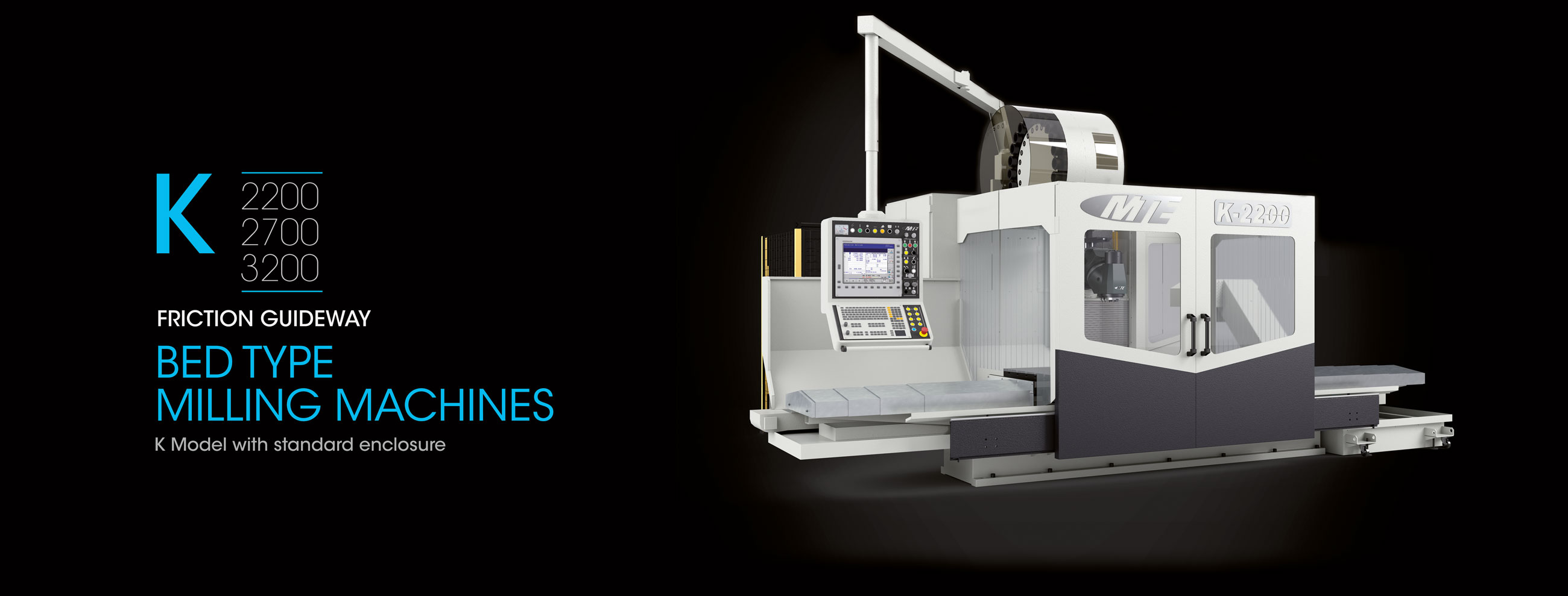

These machines can be fitted with manual or automatically swivelling milling heads, with or without tool changer, with full housing or simple splash guards for protruding workpieces. We can build your K series bed type milling machine to your precise individual specifications.

X: 2000 – 3000 mm

Y: 1000 mm

Z: 1100 mm

Y: 1000 mm

Z: 1100 mm

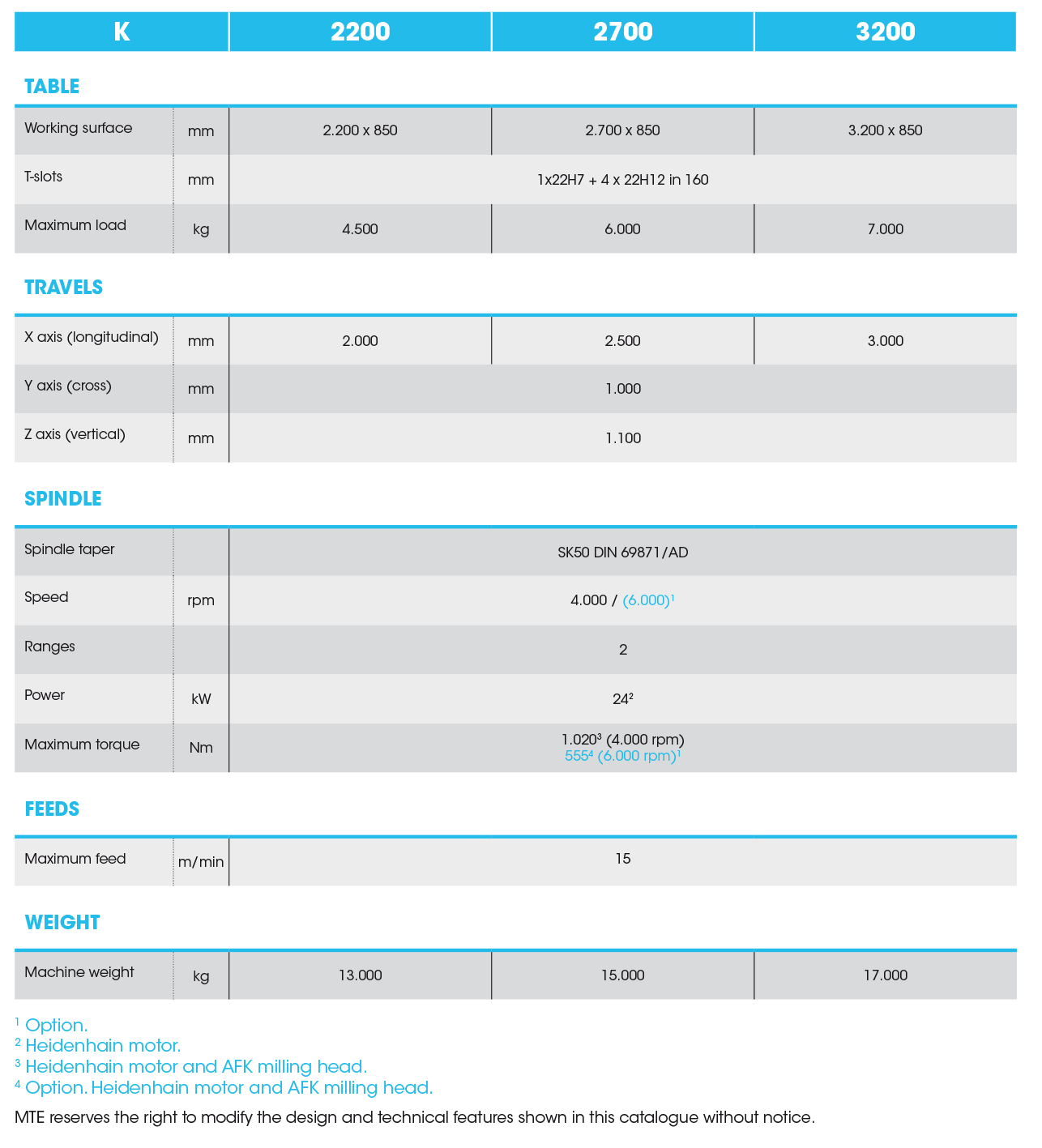

TECHNICAL FEATURES

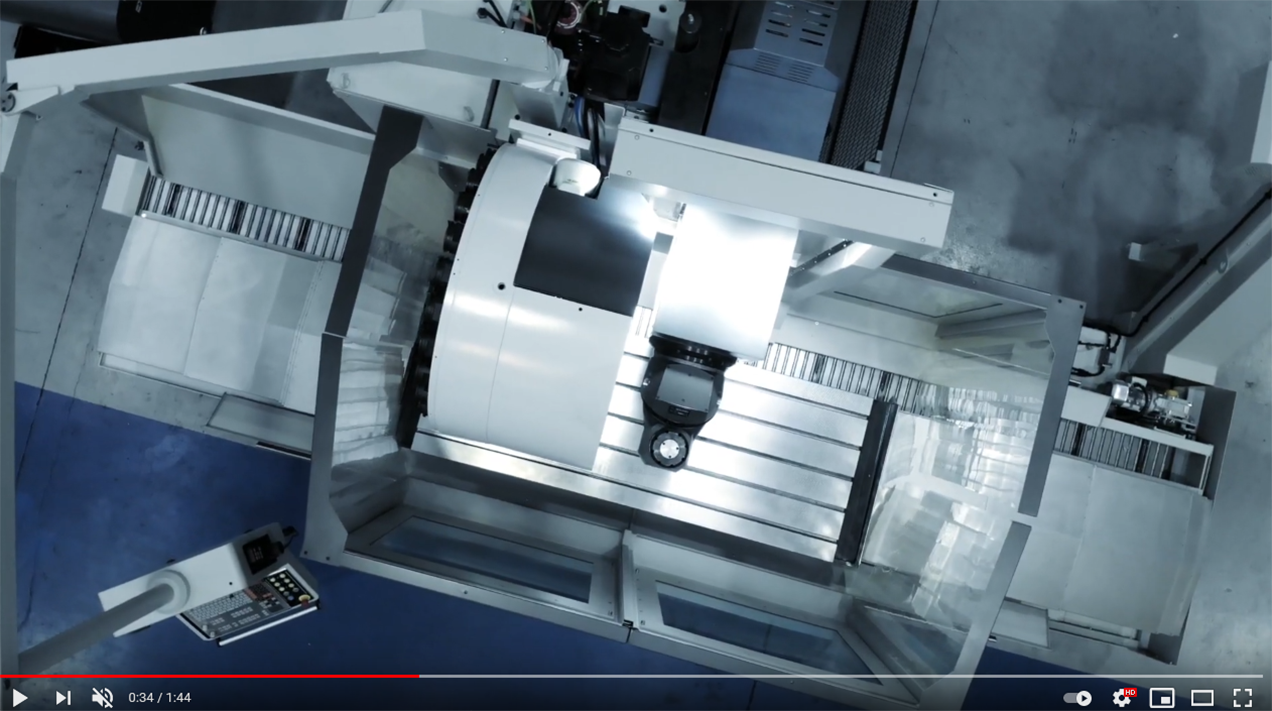

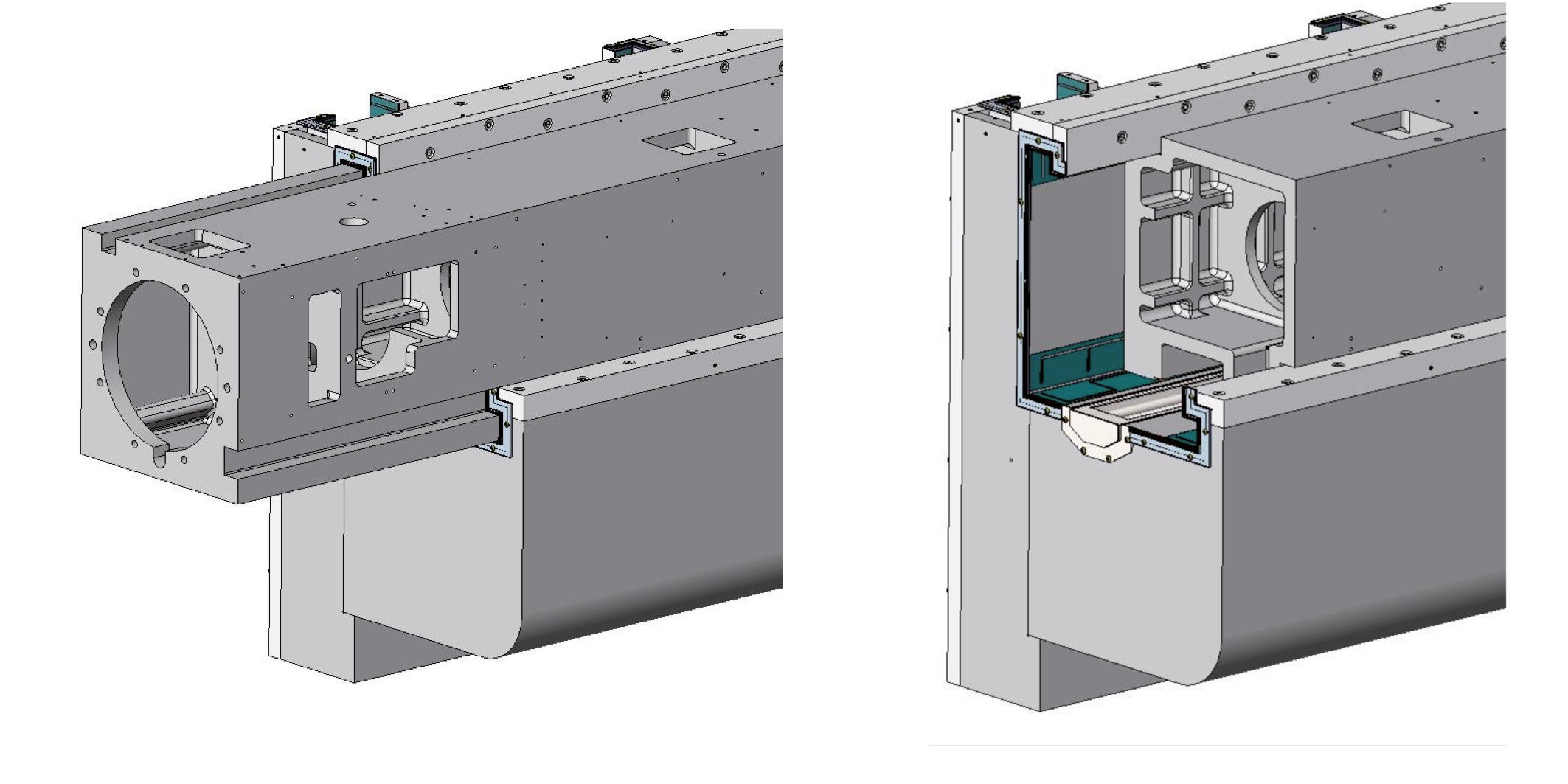

FRICTION GUIDEWAY | BED TYPE MILLING MACHINES

STANDARD EQUIPMENT

STANDARD EQUIPMENT FOR K MODEL BED TYPE MILLING MACHINES.

- Two ranges cooled gearbox

- Manual cooled milling head 4.000 rpm (MFK)

- Heidenhain CNC TNC 640

- Heidenhain direct linear scales

- Electronic handwheel

- CNC movable panel front-back side of machine

- Automatic lubrication system

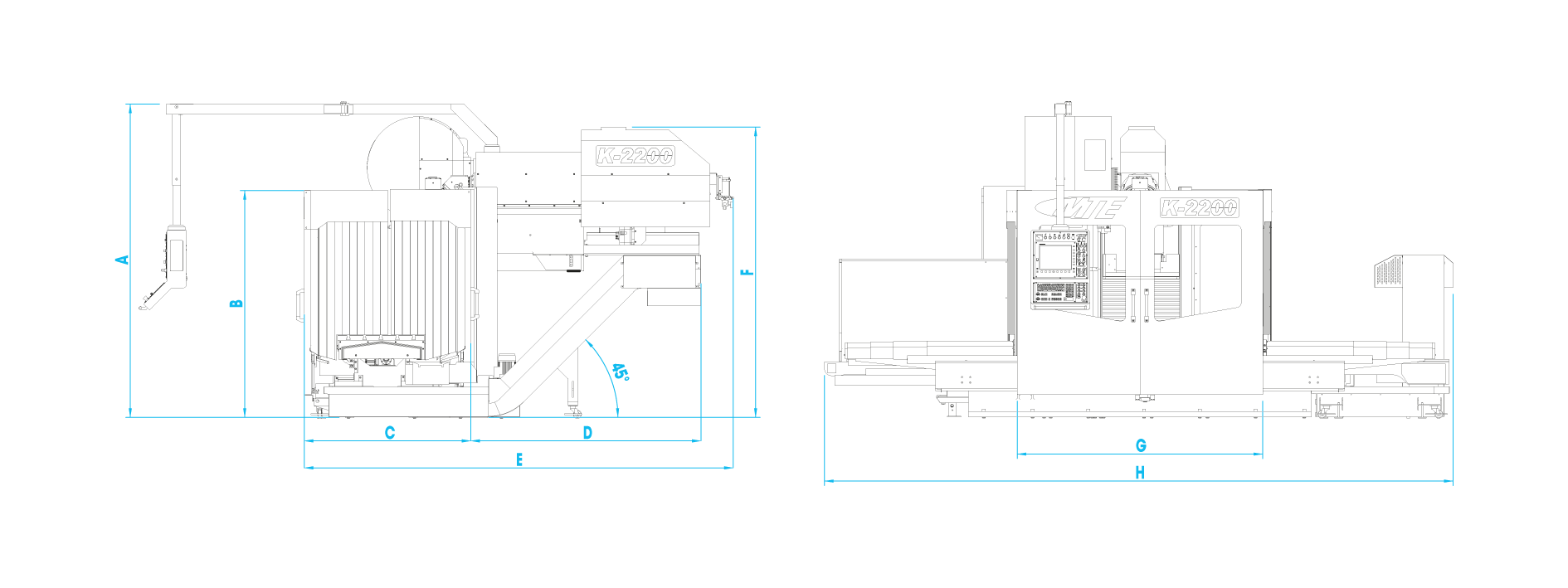

- Standard enclosure

- External coolant equipment

- Hydraulic counterbalance system

- Foot pedal

- Working light

OPTIONAL EQUIPMENT

OPTIONAL EQUIPMENT FOR K MODEL

- Manual cooled milling head 6.000 rpm (MFK)

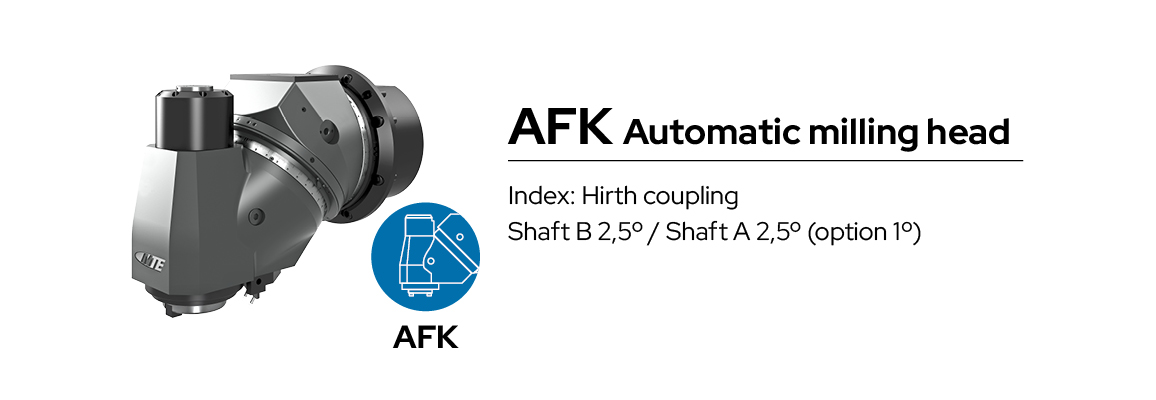

- Automatic cooled milling head 4.000/6.000 rpm 2,5°x2,5° (AFK)

- Automatic cooled milling head 4.000 rpm 2,5°x1° (AFK)

- Direct cooled spindle 4.000 rpm (HFK)

- Different CNC available: Siemens, Fanuc and Fagor

- 19 inches CNC screen

- Wireless handwheel

- Pressurized linear scales

- Teleservice

- Random vertical tool changer 24 tools

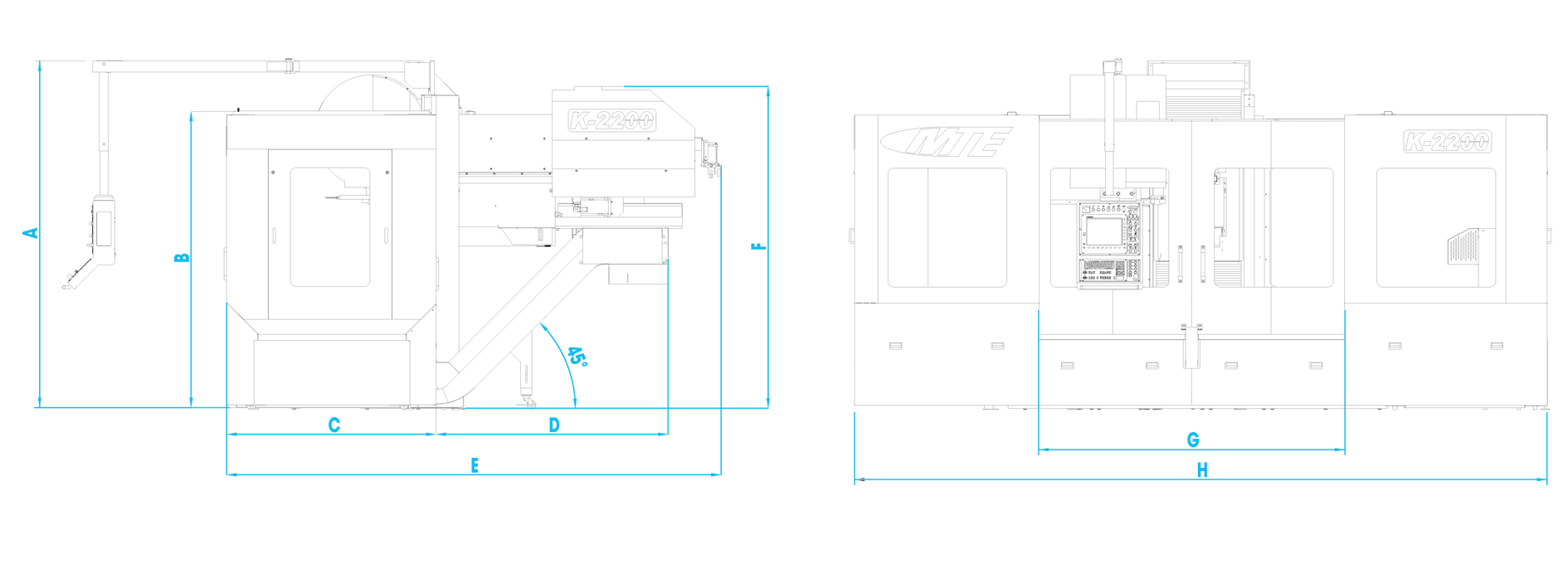

- Closed enclosure: Open Top / Full Closed

- Automatic doors for Full Closed enclosures

- Spin window system

- Exhaust system

- Chip conveyors

- Coolant through the spindle 20/50 bar with filter paper system

- Magnetic drum / Oil band skimmer + micro-oxygen / Frequency controller for the motor

- Air through the spindle / Through outside nozzles

- Coolant pistols

- Electrical cabinet cooling unit

- Fourth axis rotary tables

- Tools & piece probes: M&H, Heidenhain and Renishaw

- Brankamp CMS (Collision Monitoring System)

- MQL system

MILLING HEADS

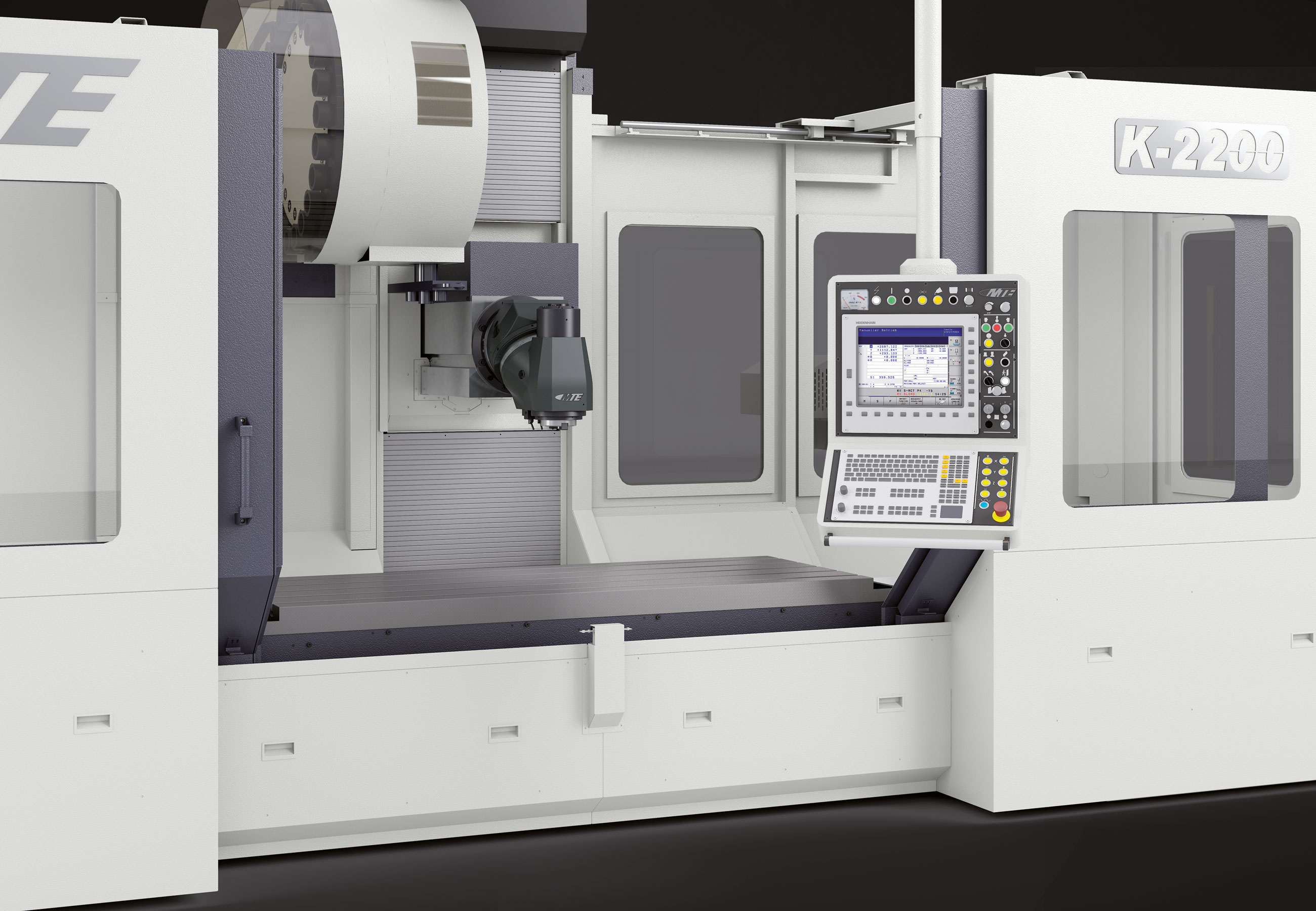

FRICTION GUIDEWAY DETAIL

MTE | MILLING MACHINES

We’re big enough to develop innovative milling technologies for the challenging global markets and flexible enough, as an owner-managed company, to deliver a highly individual and personal customer experience

SITE MAP

CONTACT

MTE Machine Tool Engineering S.A.

Polígono Industrial, Parcela M-4.1

E – 20829 Itziar-Deba (Spain)

Tel: +34 943 60 63 83

info@mtemachine.com

www.mtemachine.com

Google Maps